Cooling Tower Pump Suction Strainer

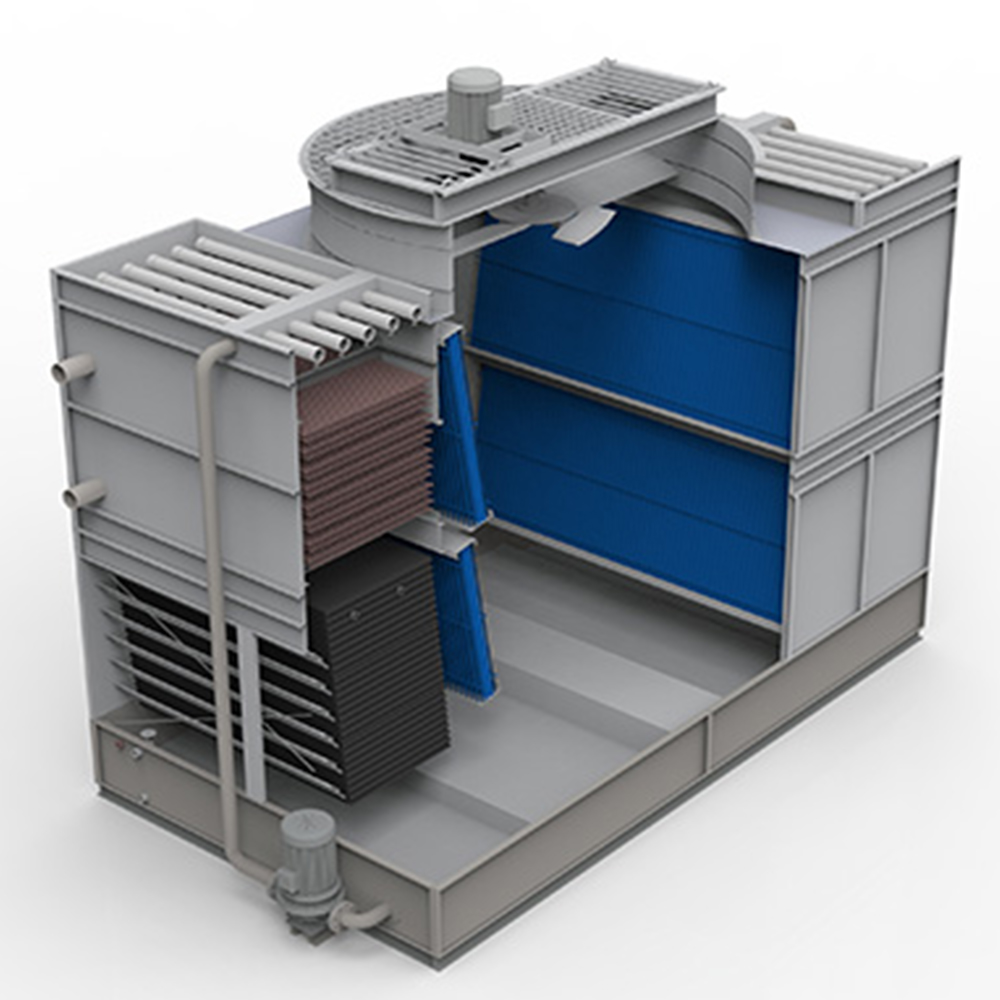

Bac offers many styles of suction strainers and suction hoods for just about any application.

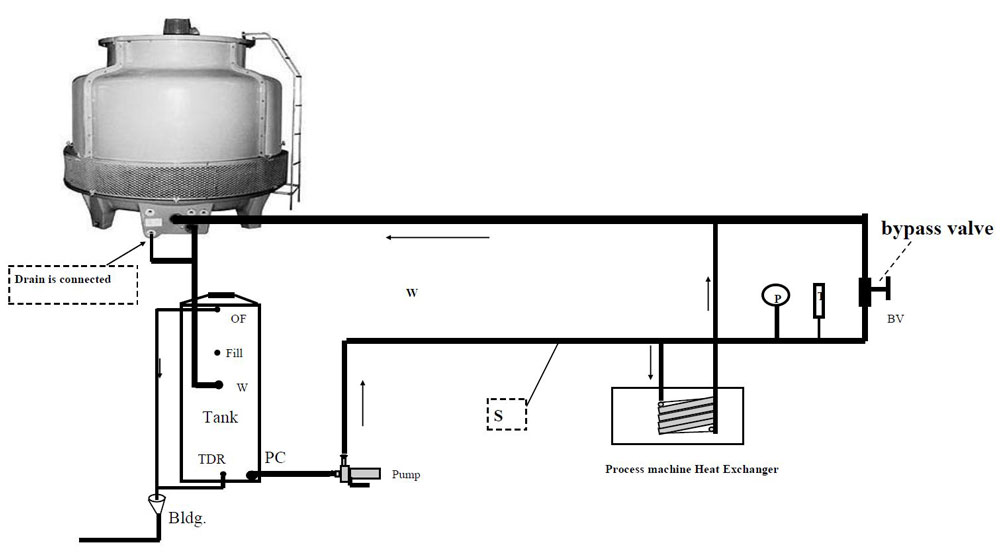

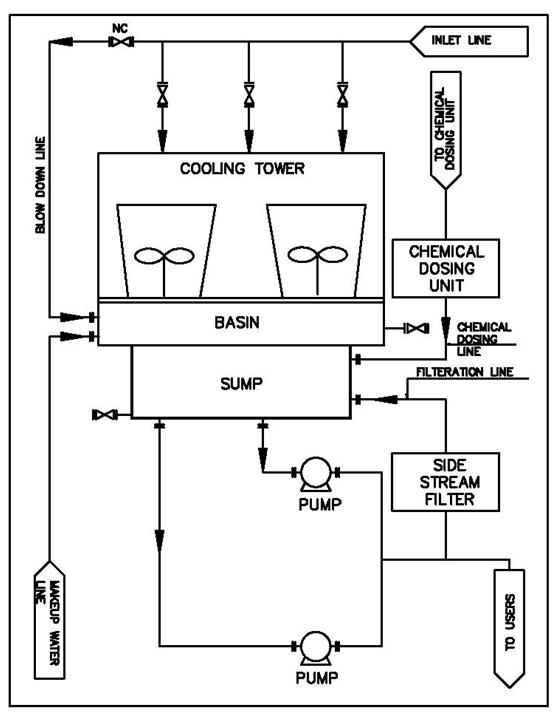

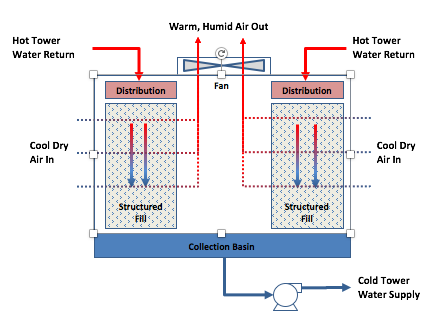

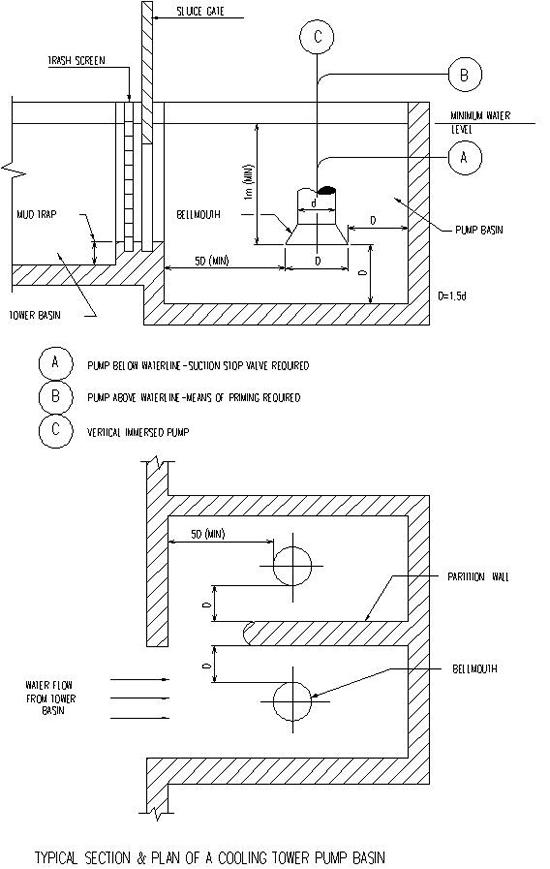

Cooling tower pump suction strainer. This pump kit is not for sale the original b g 1 4 hp pumps are obsolete and to be replaced with ebara 1 3 hp pumps. Pump suction strainers are located on the outlets of units and prevent large debris such as sticks and stones from entering the system. It must also provide the energy head necessary to raise water from a low to a higher static head level. Some fairly catastrophic events can occur if either is improperly installed.

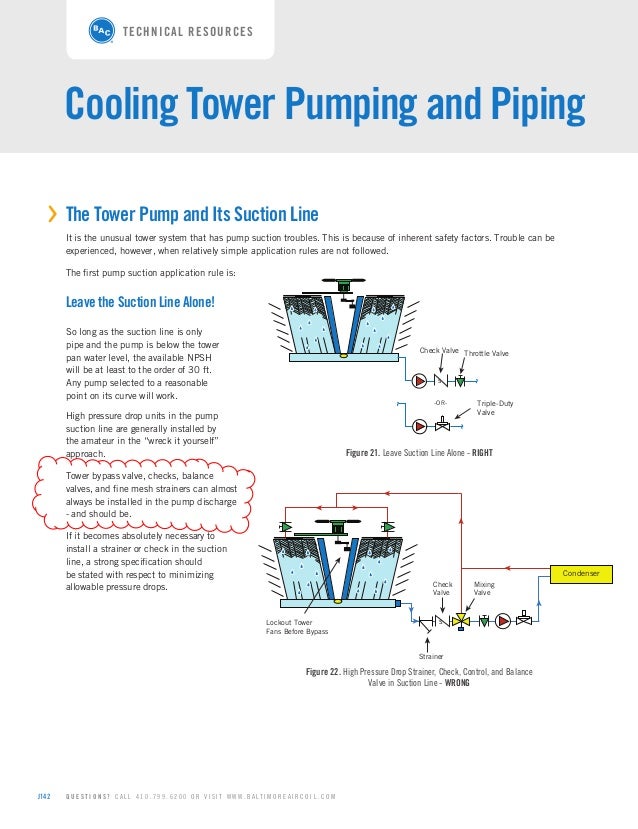

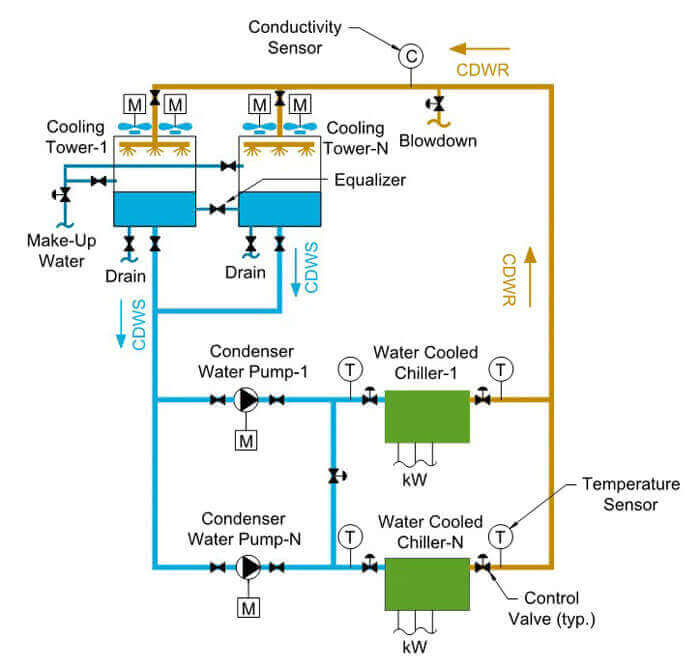

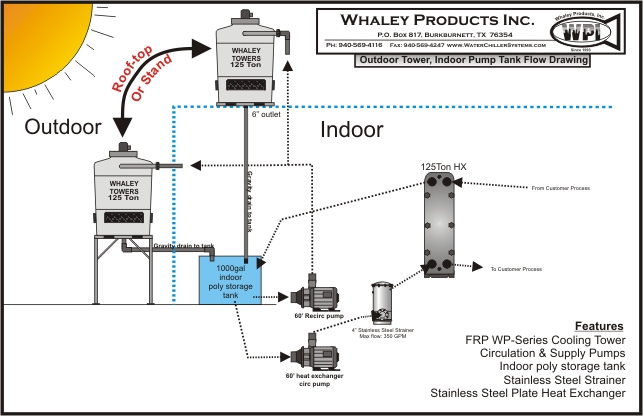

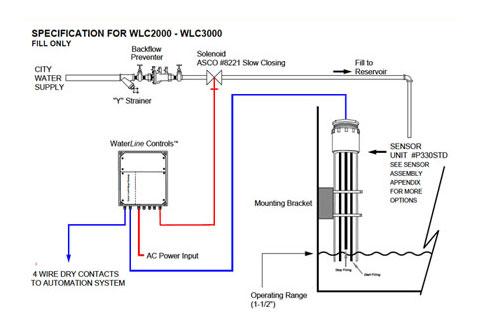

Correctly piping the suction and discharge of your cooling tower condenser water pump is critical. B lack of tower treatment with consequent fouling of the condenser. Cooling tower systems inc. Trillium pump upgraded kit contact bac warranty services.

A plugged suction strainer. Pump suction water will reach this level without pump energy. 196 lower cherry street macon ga 31201 manufacturing warehouse 196 lower cherry street macon ga 31201 toll free. Strainer perforations are spaced to provide maximum strainer free area for low pump suction losses.

This conversion requires a change in the pump transformer and other components. B g says to avoid fine mesh strainers in the pump suction. Commercial buildings sometimes use y strainers to keep their cooling towers and boilers from releasing scale into the water. Piping condenser cooling tower losses and.

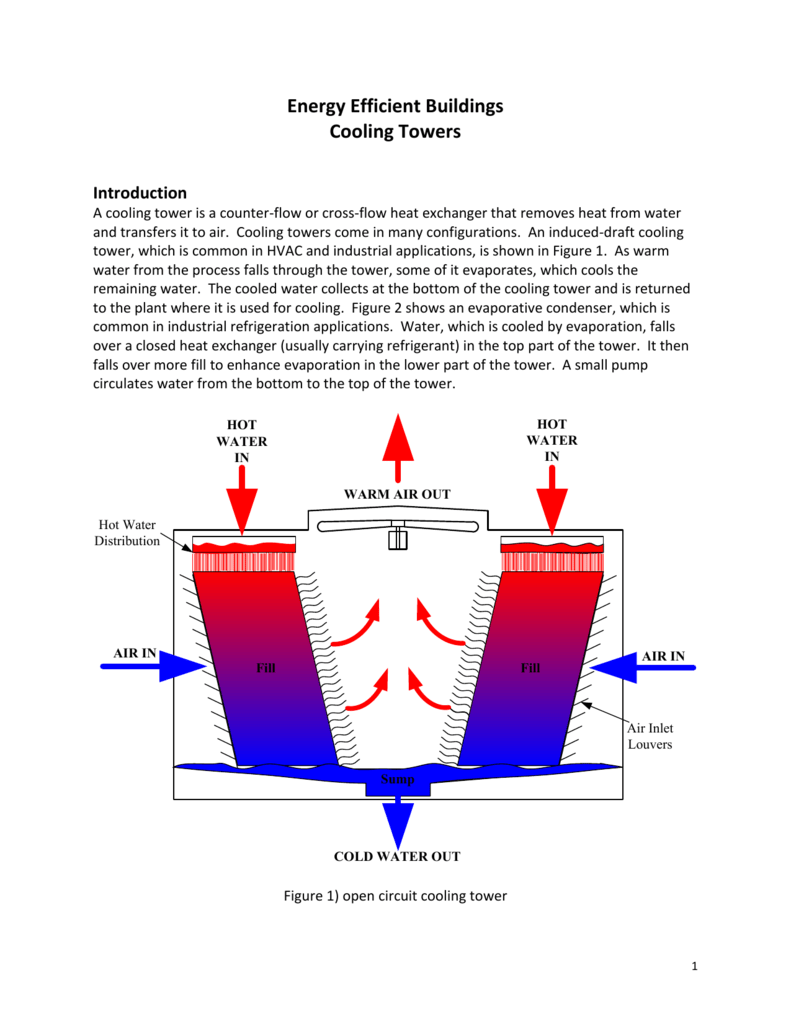

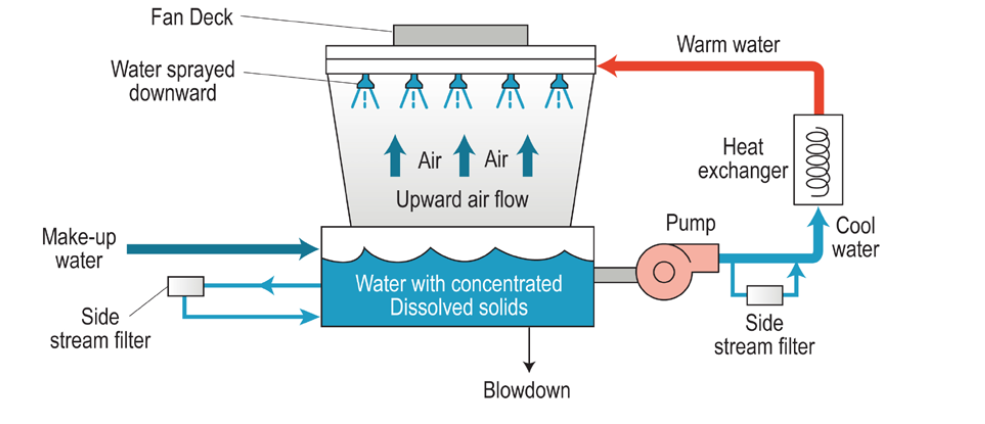

Pump suction strainers are standard on properly designed cooling towers and are just the beginning of filtration. Open tower system pump head requirements. Starting with the suction piping it is important to take precaution to avoid air pockets which can destroy a pump in pretty short order. Lakos centrifugal separators and filtration solutions continuously remove dirt and debris from cooling tower water helping maintain efficiency reduce maintenance and extend the life of cooling towers heat exchangers chillers and other hvac equipment.

Anti cavitation design prevents air from reaching the system pump. Y strainers can be used as an intermediate or even final filtering element in biofuel production if the straining element is able to keep out ultrafine particles. 3 16 strainer perforations help keep the system clean. Open piping circuit for the tower piping circuit the pump must overcome the piping flow friction loss.