Cooling Tower Pump Sizing

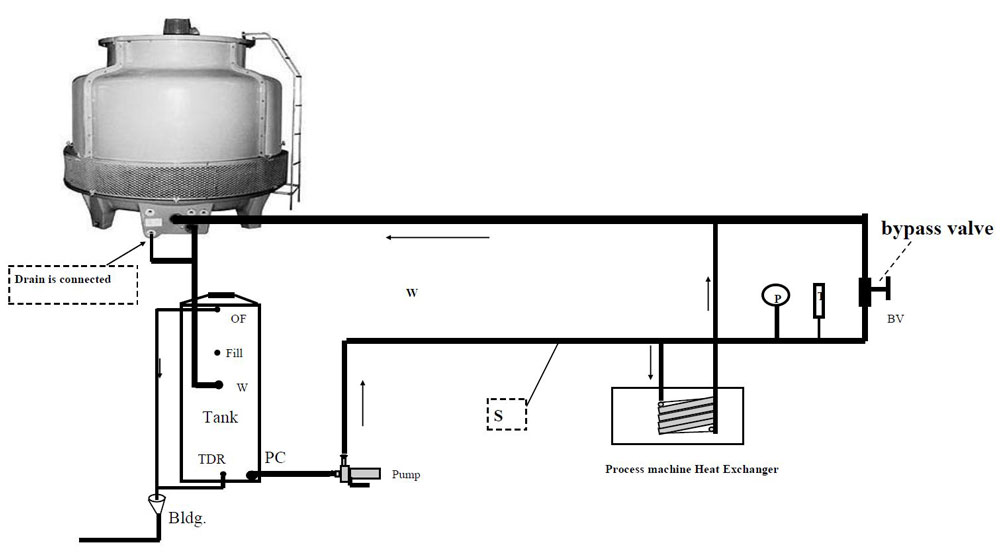

Sizing the tower water pump can be a challenge too.

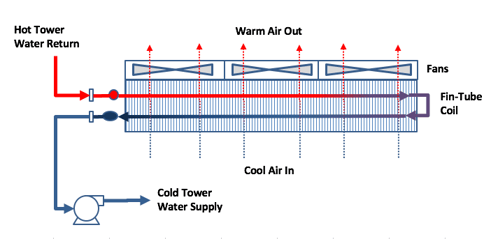

Cooling tower pump sizing. Keep in mind that you need the pump to develop enough pressure to get water to the highest and farthest places in the plant. Pumps are typically sized for 65 feet of head. In order to understand how these factors influence cooling tower size it is first necessary to give the terms some context. Heat load btu hr gpm x 500 x.

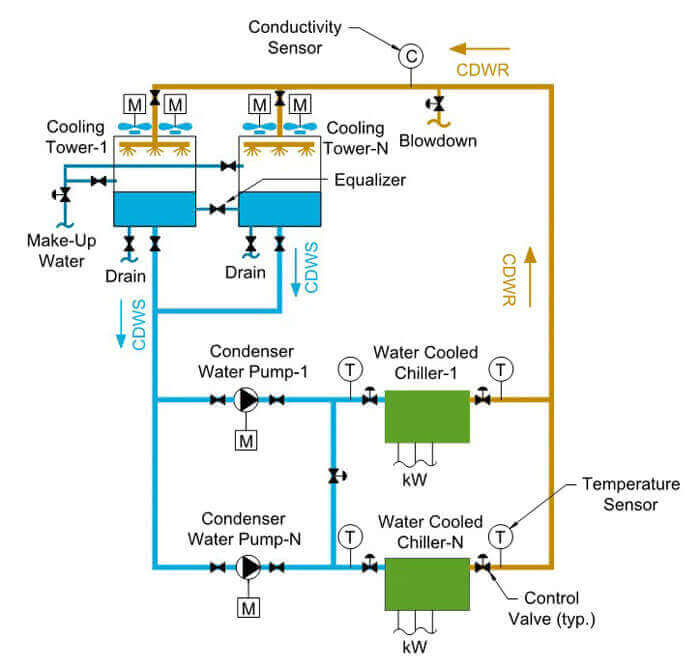

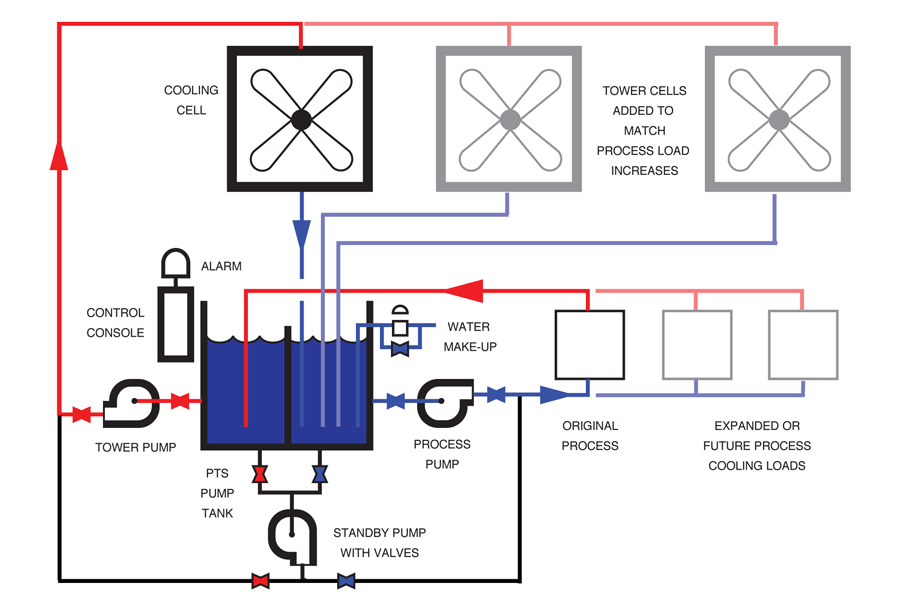

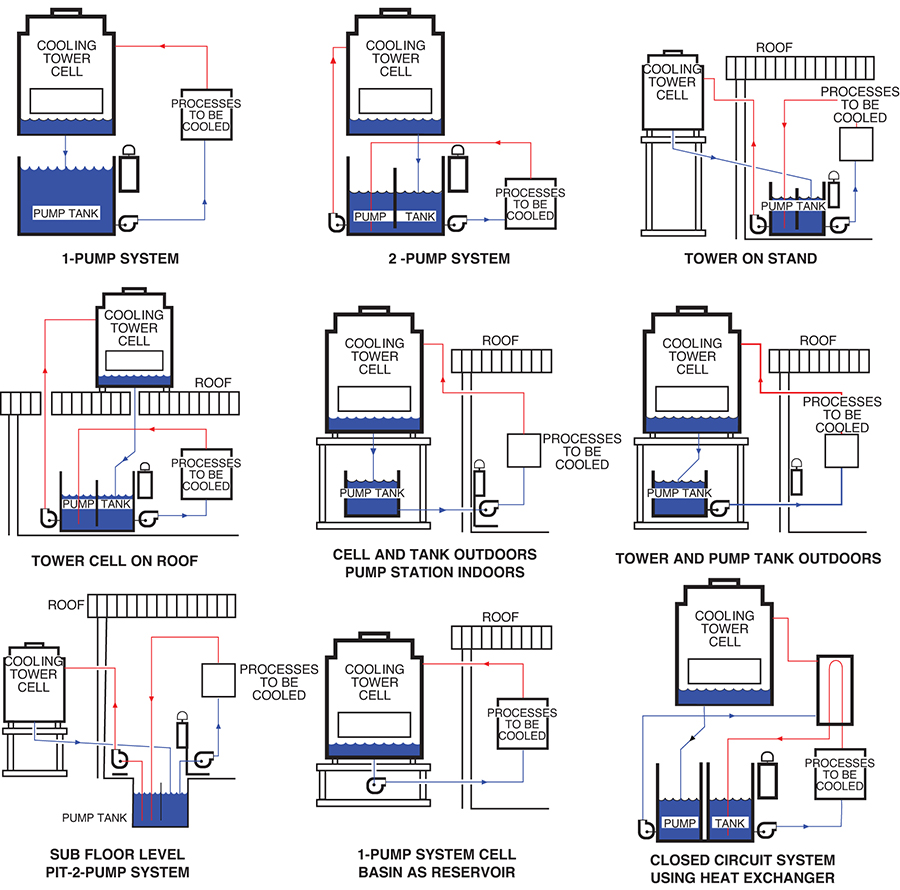

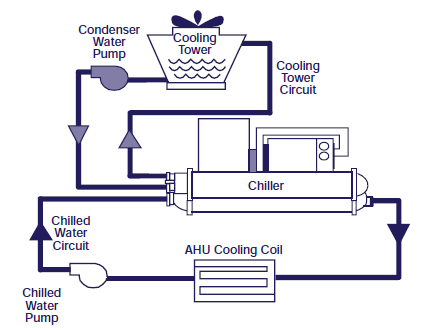

The following design data is required to select cooling towers. Remember ashrae now assigns a maximum pipe size on cooling tower condenser water systems. The required cooling tower design and size will be a function of following values. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet bulb air temperature or in the case of closed circuit dry cooling towers rely solely on air to cool the working fluid to near.

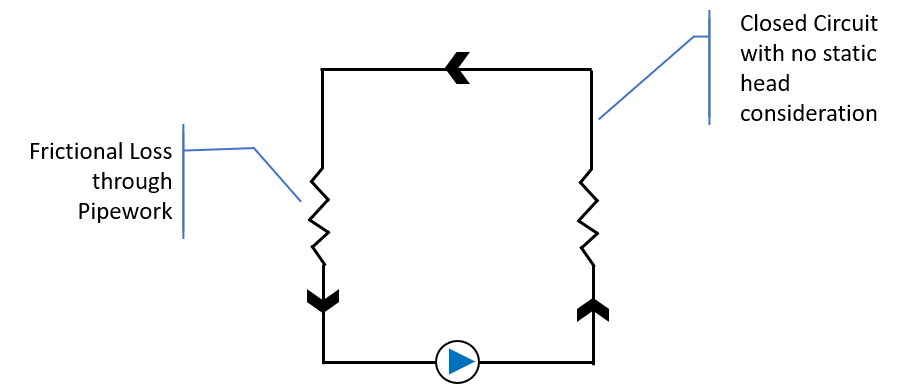

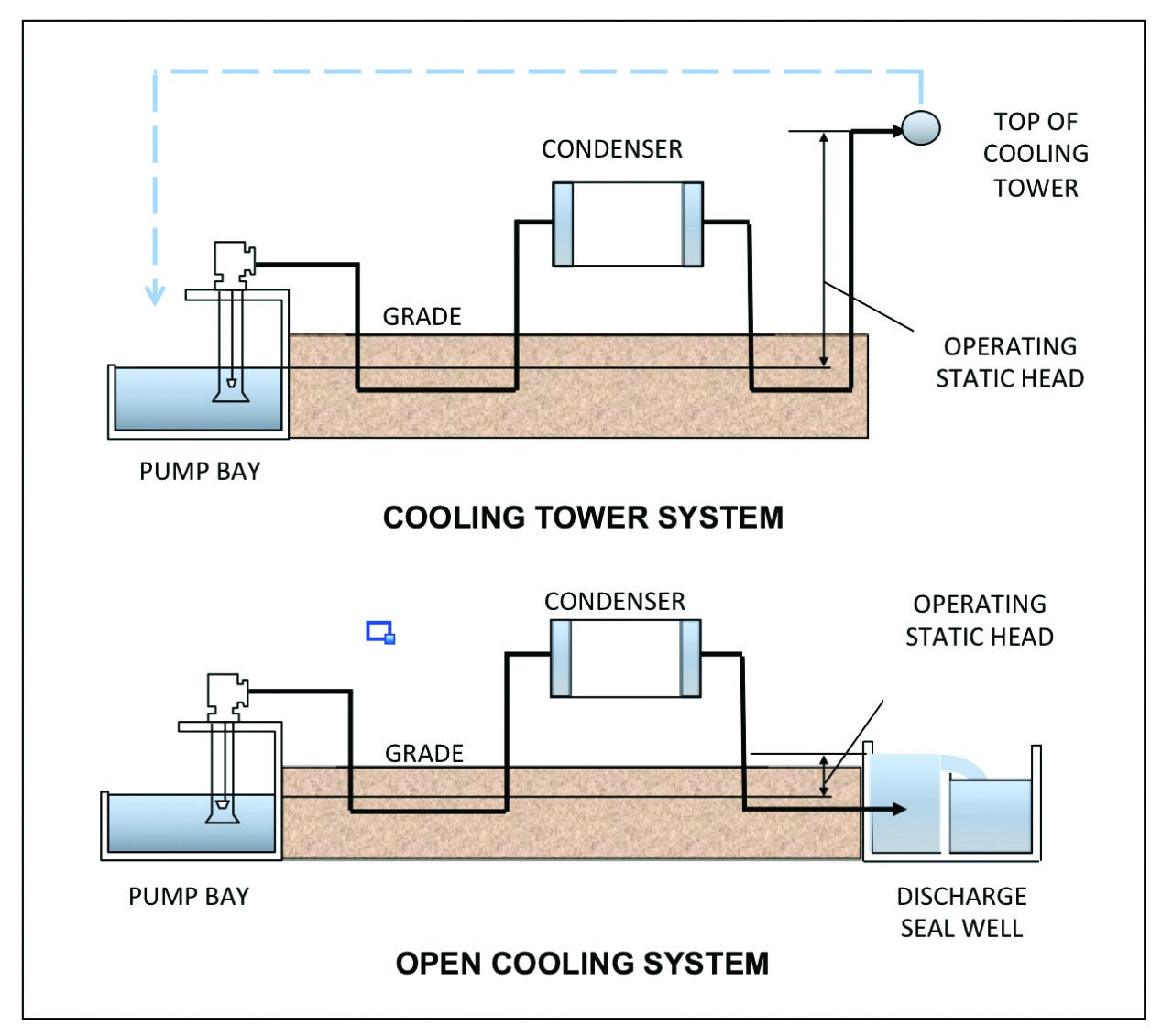

It must also provide the energy head necessary to raise water from a low to a higher static head level. Heat load range approach and wet bulb temperature. Cooling tower sizing program. We can help you size your pump based on your requirements.

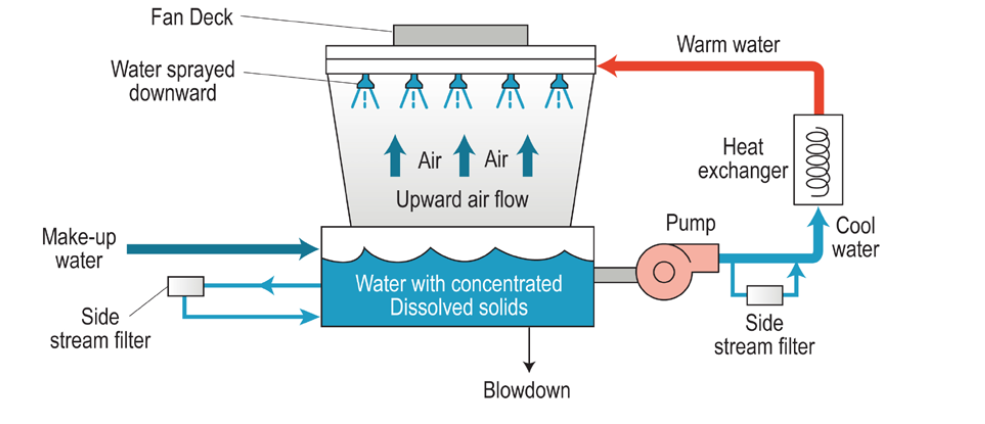

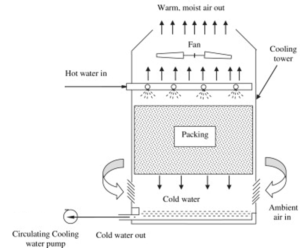

Flow feet of rise run line loss pressure loss in process equipment and pressure loss in any utilized integrated. A cooling tower is a heat rejection device that rejects waste heat to the atmosphere through the cooling of a water stream to a lower temperature. For the tower piping circuit the pump must overcome the piping flow friction loss. Range of cooling in f t1 t2 area wet bulb temperature in f twb the design heat load is determined by the flow rate and the range of cooling and is calculated using the following formula.

For most wet cooling tower applications optimum cooling tower size may be determined by a combination of four different metrics. Size the pump discharge piping per ashrae 90 1 2010 design tables. B web bulb temperature. C approach to wet bulb temperature d mass flowrate of water circulation rate.

Wpi can provide you with a pump to supply you process or application. Include a fouling factor on pipes when sizing your pump. Piping condenser cooling tower losses and valves. Flow rate in gpm.