Cooling Tower Preventive Maintenance Checklist

Keeping your cooling tower running.

Cooling tower preventive maintenance checklist. The cold water basin should be flushed and cleaned with the suction strainer screens in place. The 14 maintenance checklist mentioned above will greatly help you determine possible problems on the cooling tower system fix. Following the recent legionnaires disease outbreaks there is a great deal of concern and uncertainty about what is required for proper cooling tower maintenance. Back to faqs definitions.

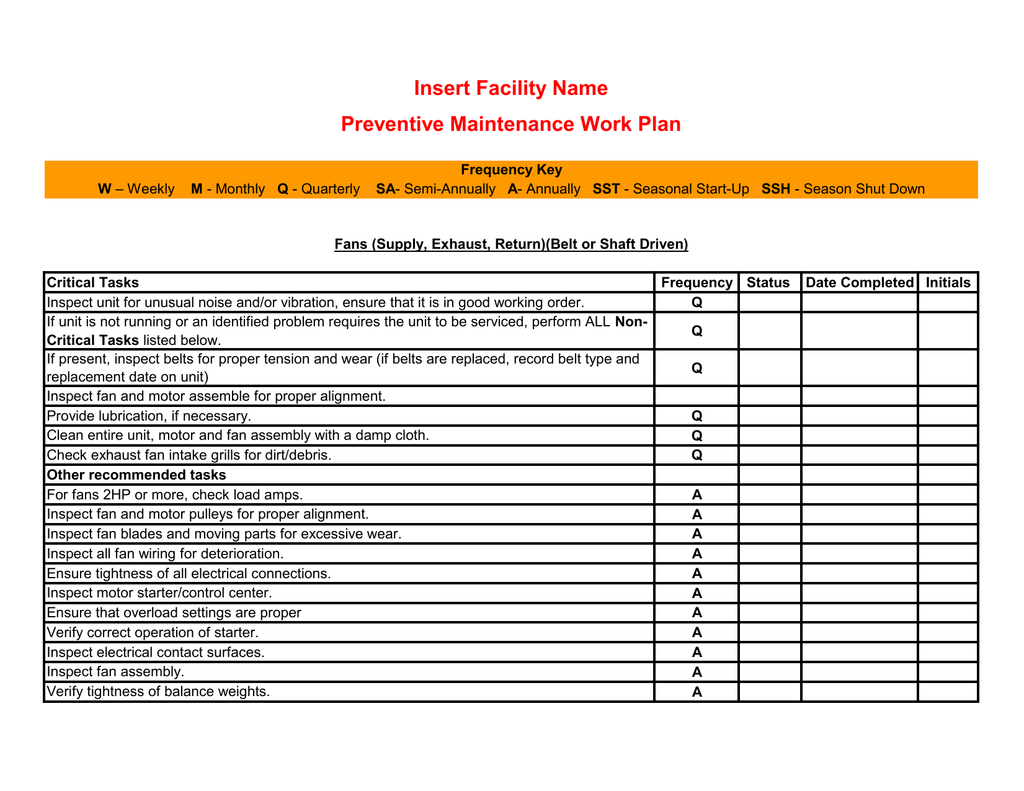

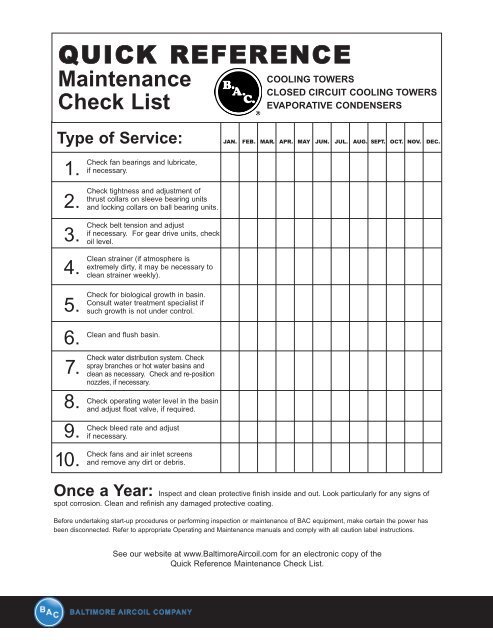

Consult your product specific o m manual before conducting maintenance on the unit. Stick to a regular maintenance schedule to reduce the risk of legionella and prevent premature failure recommends dan glover technical services group manager for southland industries a national mechanical engineering construction and service firm. This content has been revised as per the new nyc cooling tower legislation. Operation and maintenance instructions seasonal shut down checklist when the system is to be shut down for an extended period of time the following services should be performed.

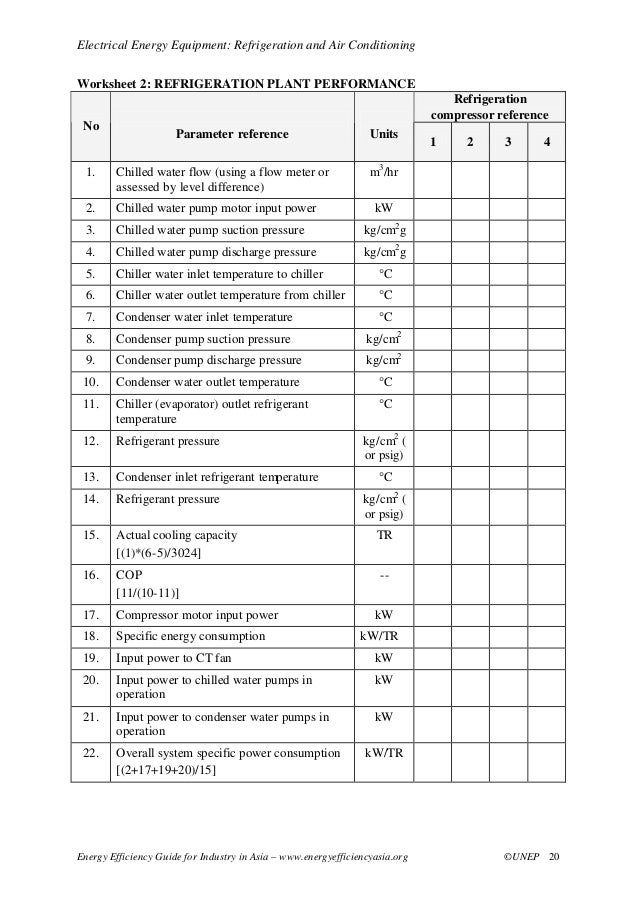

See the updated article. The evaporative cooling unit cold water basin should be drained 2. The program is designed to. The purpose is to define a preventive maintenance program and plan for cooling towers at the suny polytechnic quad c building utica new york.

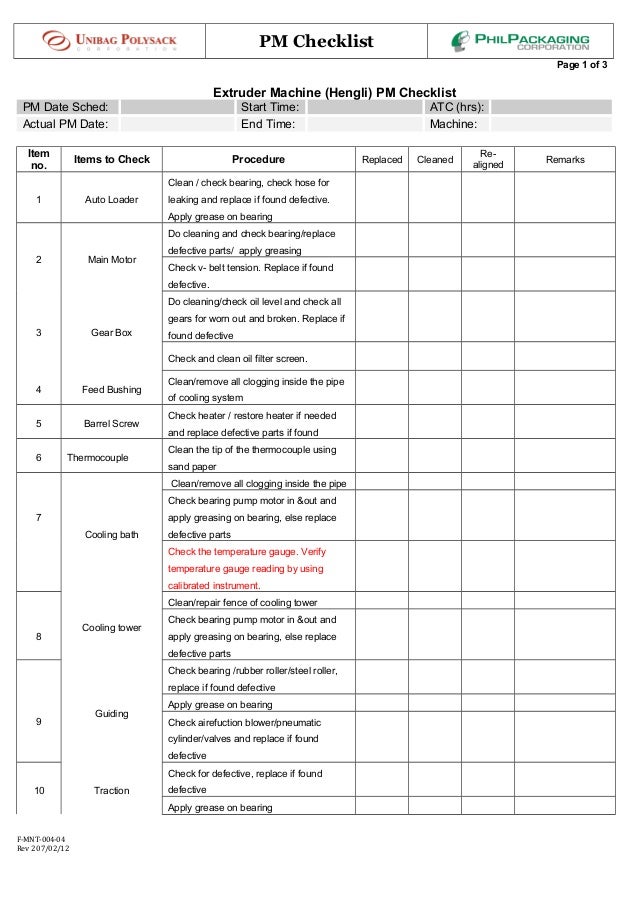

Preventive maintenance checklist preventive maintenance tasks on cooling towers should be conducted daily weekly semi annually or annually depending on the task. Cooling towers evaporative condensers and closed circuit cooling towers. Different environmental conditions may dictate more frequent servicing. Keeping your cooling tower in good shape requires more than just the annual inspection before startup.

Cooling tower maintenance checklist for nyc following the legionnaires disease outbreak in new york city this past summer there is a great deal of concern and uncertainty about what s required for proper cooling tower maintenance. Cooling tower inspection checklist and calendar general recommendations more frequent inspection and maintenance intervals may be desirable. Recommended service intervals are the minimum for typical installations. The frequency of maintenance procedures varies depending on various factors like the condition or quality of the water circulating in it as well as the location and environment where the cooling tower operates.

1 2 maximize equipment life span. Each day technicians should perform an overall visual inspection when they sequence coolers and ensure that water is flowing appropriately. Cooling tower preventative maintenance checklist.