Cooling Tower Chemical Feed Systems

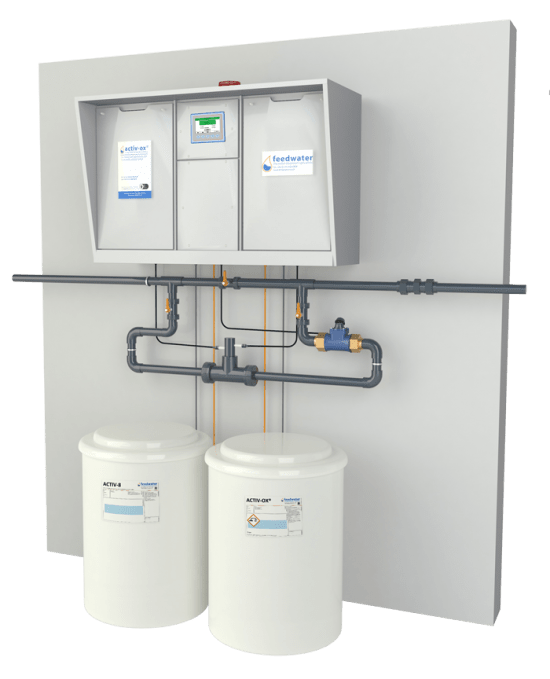

Install automated chemical feed systems on large cooling tower systems more than 100 tons.

Cooling tower chemical feed systems. Cooling tower water is prone to foaming due to the overfeeding of biocides and similar issues. Cooling tower chemical feeders accurately meet precise chemical treatment requirements. A robust scale corrosion inhibitor program should be accompanied by a biocide program to fit your needs. Cooling tower chemical treatment.

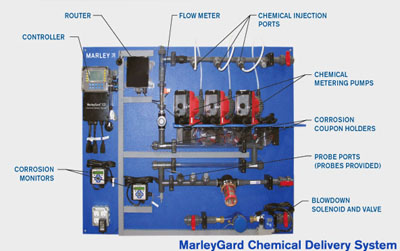

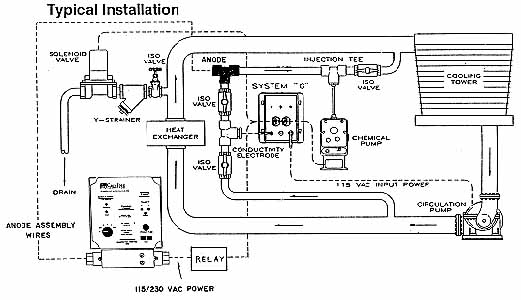

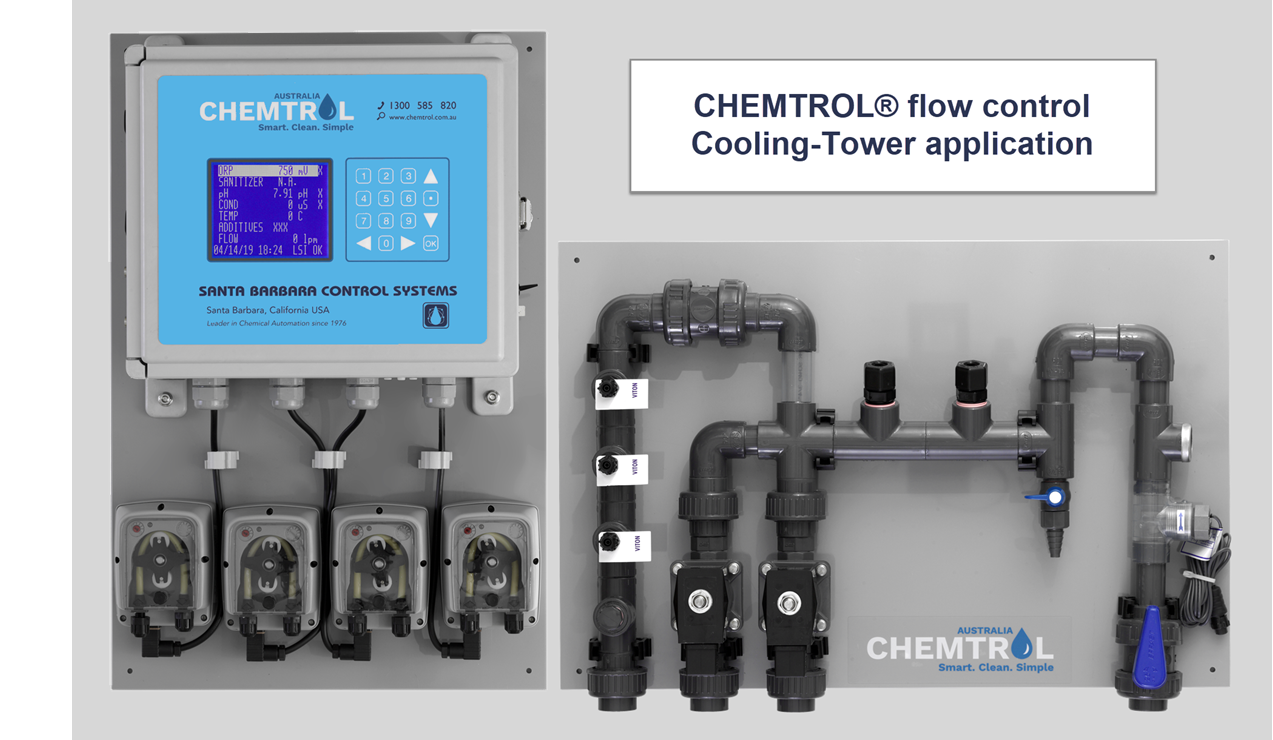

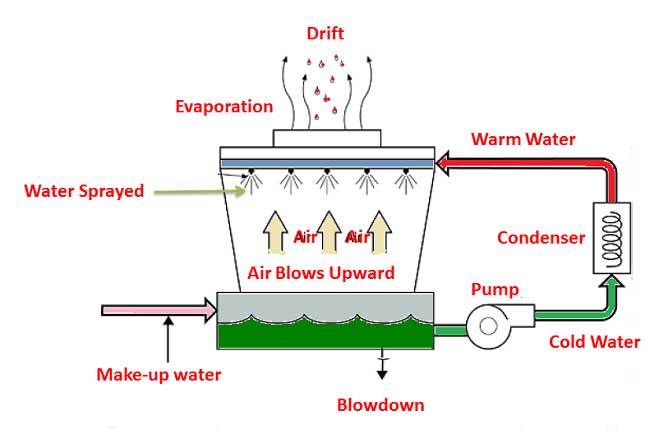

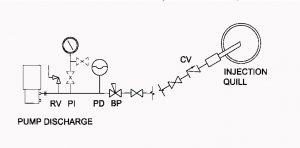

Monthly chemical treatment service recommended for all cooling tower systems and twice per month service for larger systems. Cooling tower chemicals will help maintain efficiency by preventing corrosion scale deposition and biofilm growth. A cooling tower water treatment system is an arrangement of technologies that remove damaging impurities from your cooling tower feed water circulation water and or blowdown. The automated feed system should control chemical feed based on make up water flow or real time chemical monitoring.

This happens due to blowdown drift loss of water from the system plus the addition of new makeup water in the system. It is a measurement of time at which the concentration of the added chemical into the cooling water system decreases to 50 of its original value. Anti foaming chemicals help to eliminate excess foam in the system. Chemical treatment program designed to prevent calcium scaling control corrosion and regulate mircrobiological contamination.

Aql 30000 kt scale sludge and corrosion inhibitor for cooling towers with stressed water conditions. We offer chemicals. Even with the best chemical treatment program impurities in the cooling tower can only be allowed to accumulate to a certain level before the scaling potential overwhelms the chemical treatment. Cooling tower chemical feed.

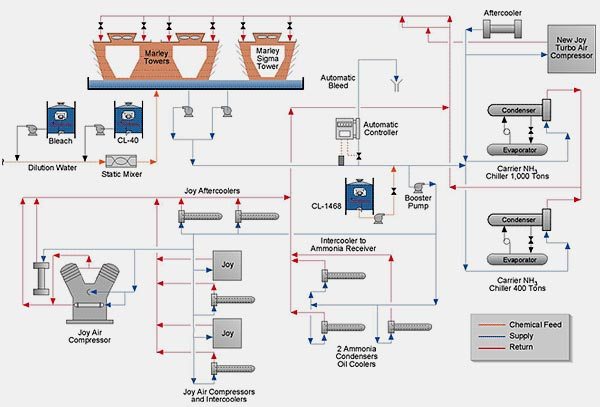

Nalco water offers a full array of solutions including chemicals equipment automation and software designed to safely optimize cooling system performance while conserving water and minimizing waste. Aql 30000 kt is specially formulated to inhibit the formation of hard water scale and control corrosion of ferrous and nonferrous metals in open recirculating cooling tower systems. Venturi based metering systems offer a full range of chemical feed rates extreme chemical resistance and engineered flexibility for a variety of industrial applications. Industrial cooling tower and closed loop efficiency can be adversely affected by corrosion scaling fouling and biological contamination.

These systems minimize chemical use while optimizing control against scale corrosion and biological growth. The specific configuration of your system will depend on several things including.