Cooling Tower Basin Cleaning Equipment

Cooling tower cleaning with rydlyme can all be accommodated during the normal operation of the cooling tower without shutdown.

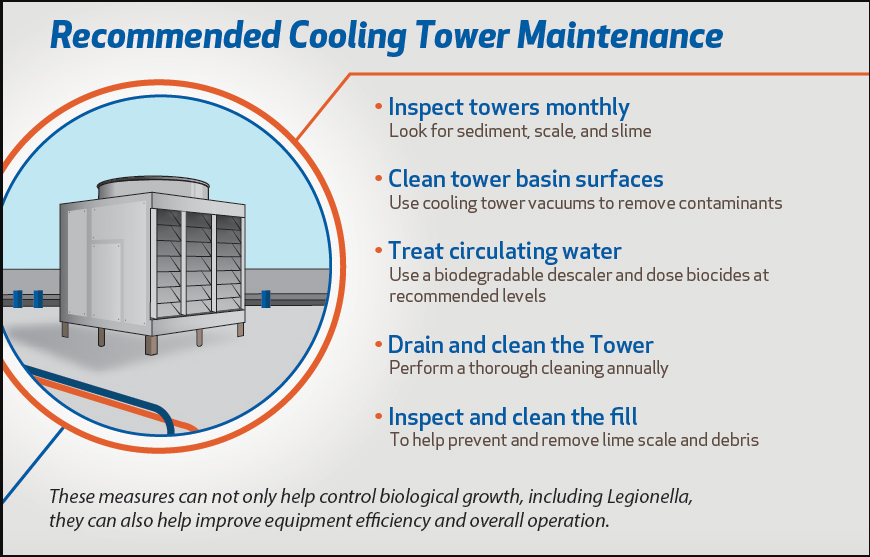

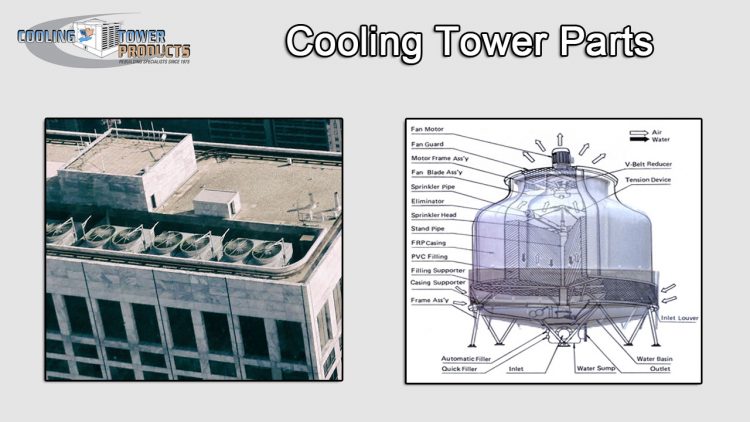

Cooling tower basin cleaning equipment. Olc services not fancy just rugged reliable performance. Cooling tower cleaning and maintenance. Cooling tower basin. Remove debris and sludge from the basin while the tower remains in service.

Suddenly there s a thick layer of sludge and slime at the bottom of the tower in the basin. In houston texas a regional laboratory for a leading environmental agency was having problems with dirty cooling tower water which lead to hvac loop system downtime and increased labor and maintenance costs. These large volume areas are extremely critical as they see a large amount of the cooling water. It is imperative when calculating a required amount of rydlyme needed for a cooling tower system to include.

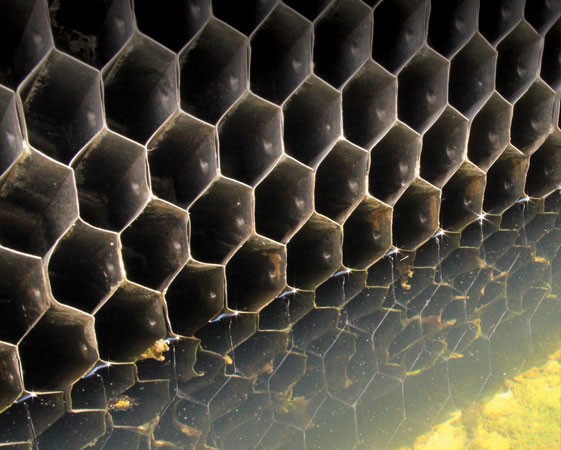

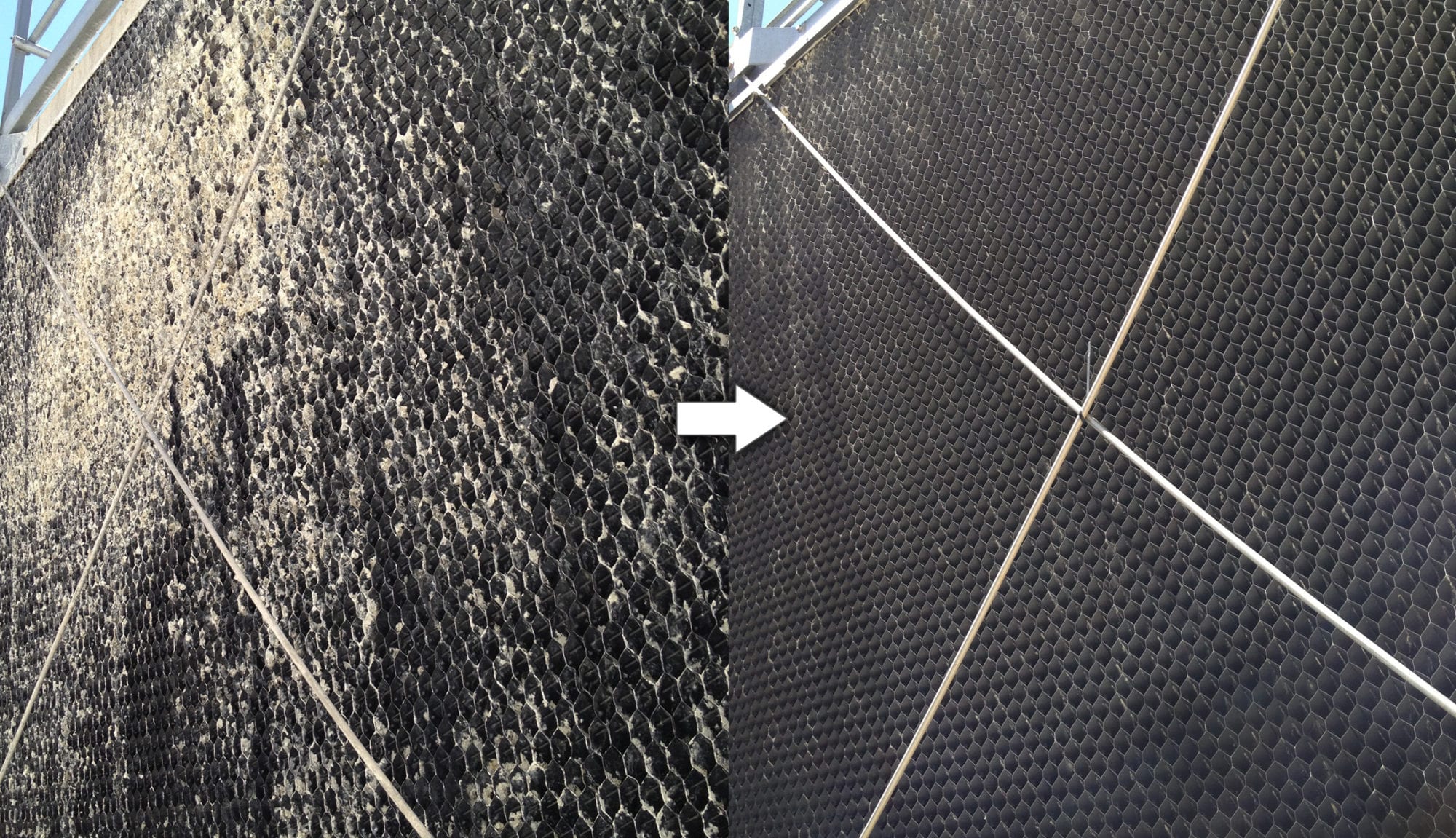

After all every tower cleaning robot does exactly the same thing. Cooling tower water that s dirty can clog fill media and foul tubes in your chiller. With wind kicking up dirt sand leaves and other debris it s no surprise that cooling towers get absolutely filthy. Cleaning and maintenance processes include but are not limited to high volume pressure washing brushing scraping vacuuming and chemical cleaning.

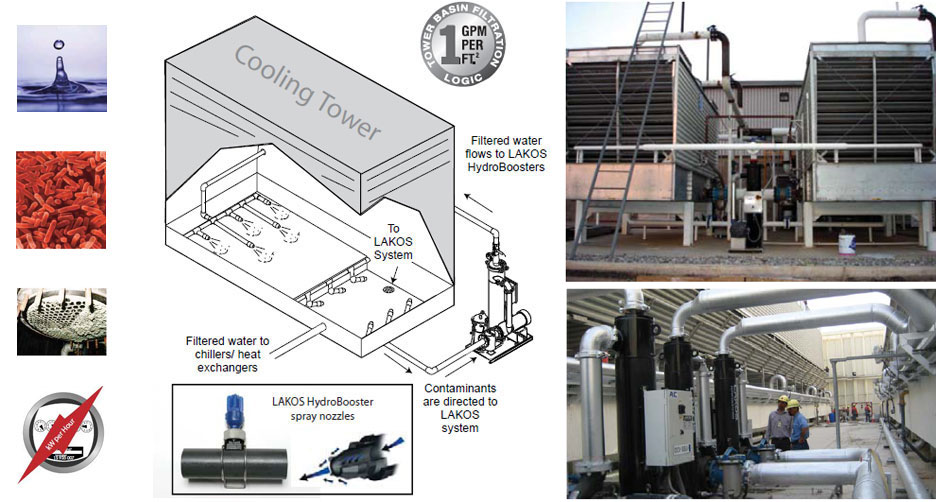

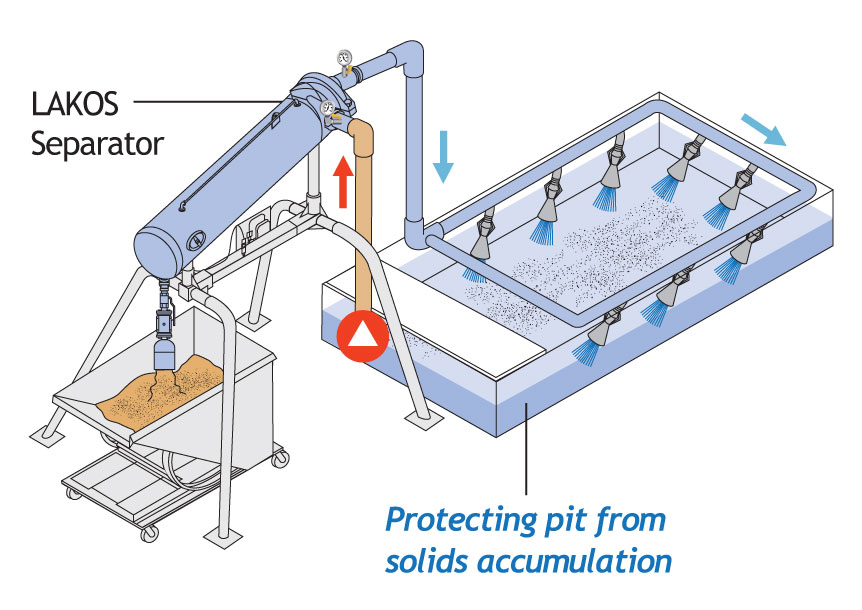

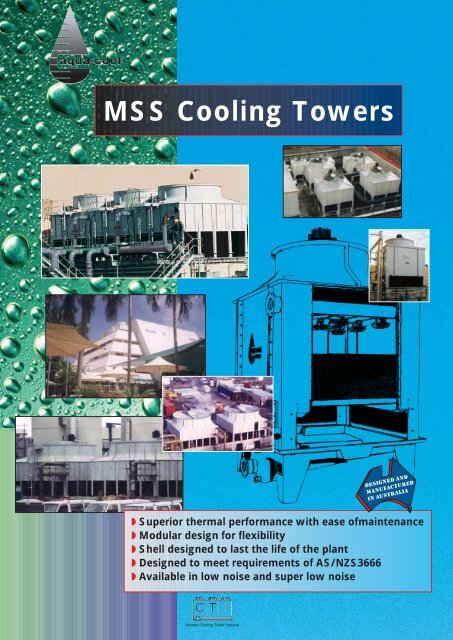

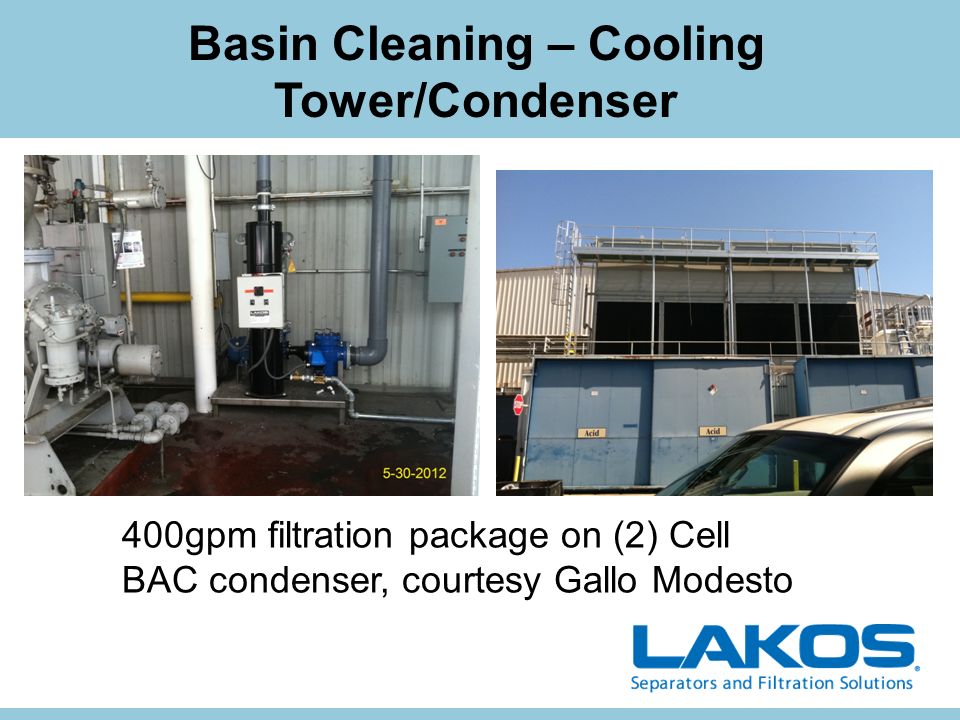

Lakos separators keep cooling towers heat exchanger. A cooling tower is a heat rejection device that rejects waste heat to the atmosphere through the cooling of a water stream to a lower temperature. The modular concept allows unmatched flexibility for the cleaning of deep basin cooling towers and tanks. Step by step cooling tower cleaning.

Proper use of recommended equipment respiratory protection personal protective equipment ppe and other safety measures. Goodway cooling tower cleaning systems make ongoing maintenance fast and easy. Anything more is just to impress. Cooling tower basin cleaning and maintenance tower basins should be cleaned and disinfected as well.

Downtime eliminated reduced maintenance costs on cooling tower basin cleaning. Cooling towers may either use the evaporation of water to remove process heat and cool the working fluid to near the wet bulb air temperature or in the case of closed circuit dry cooling towers rely solely on air to cool the working fluid to near. Cooling towers are collection areas for mud sludge and bacteria. Your tower hygiene team will clean and disinfect this area in an effort to prevent the spread of airborne pathogens and minimize the risk of corrosion.