Compressed Air Surge Tank

Download ir in line air surge tank.

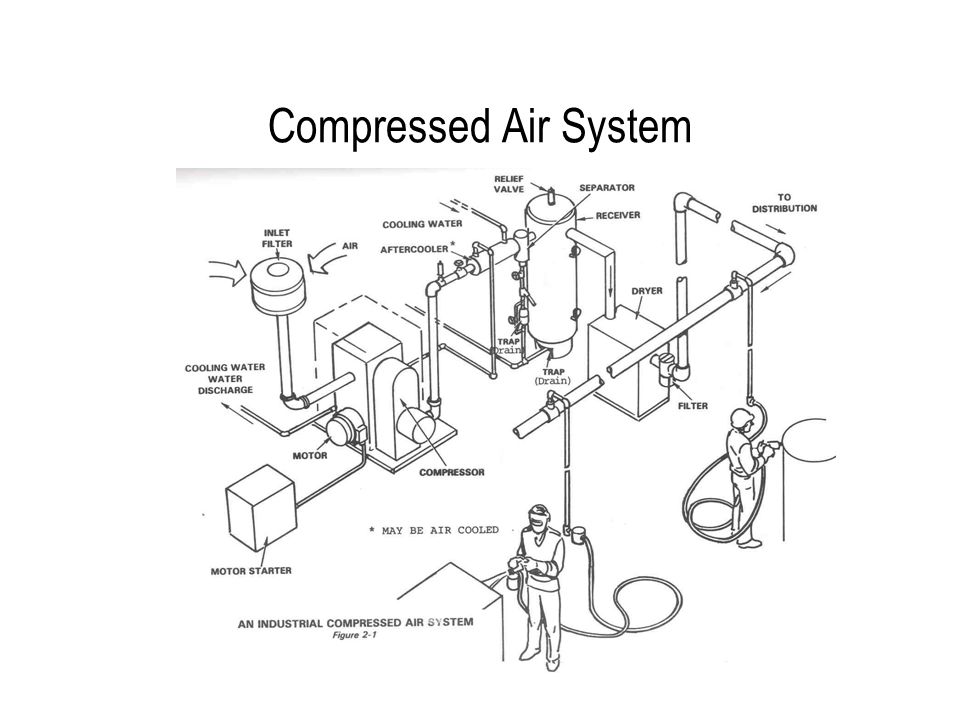

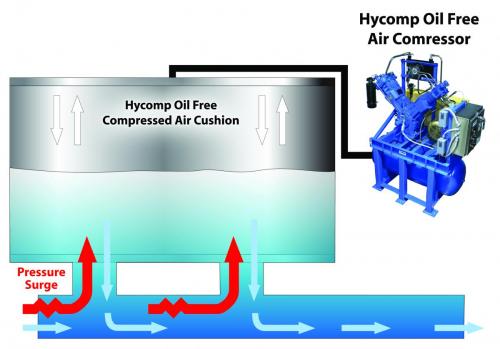

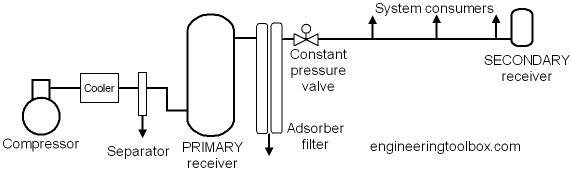

Compressed air surge tank. Find out more. Once the tank is filled with enough air the tool or equipment can run. The receiver tank is usually 150 cubic feet minimum for compressors with a rating of 25 scfm at 100 psi. Surge tanks are commonly arranged with a compressor or compressors to provide additional air in to the tank if the liquid level rises above the normal condition.

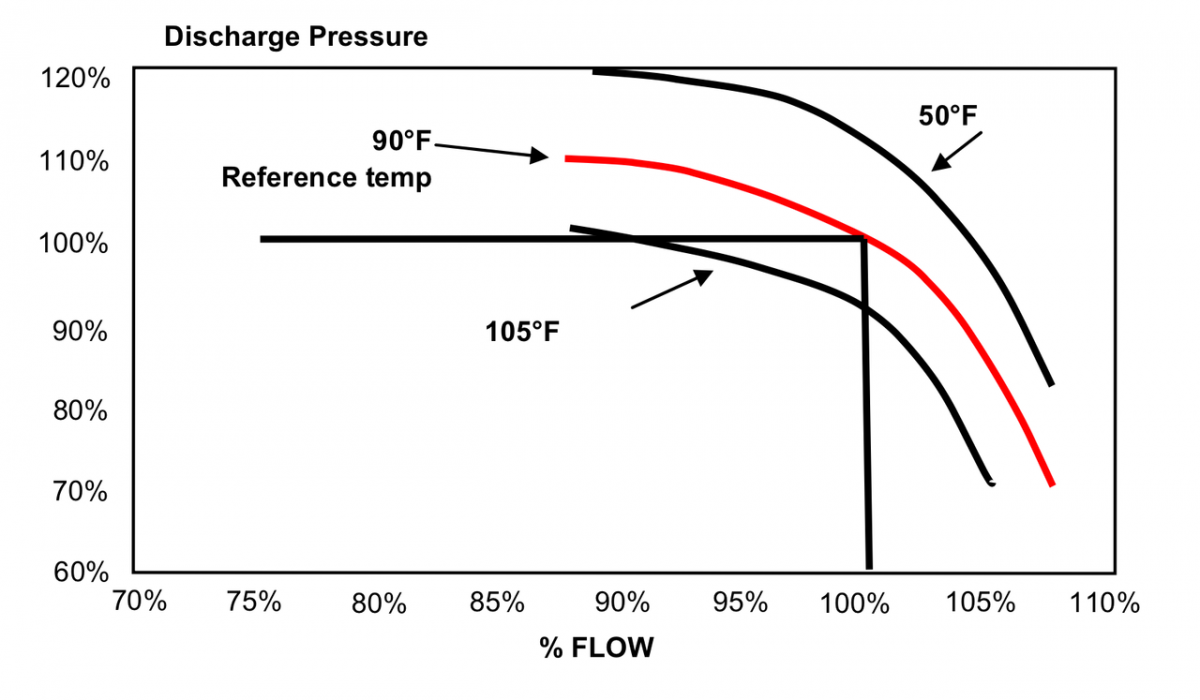

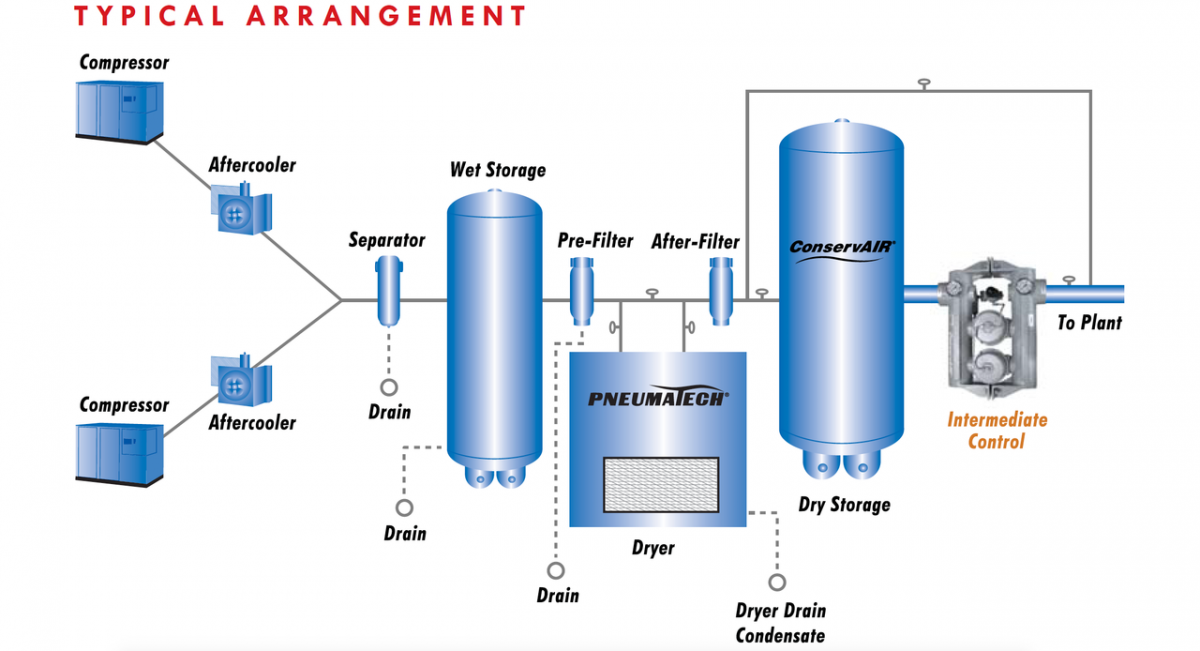

Small air receiver surge tank is designed for point of use air storage. Storing your tank outside avoids excess heat buildup in the compressor room and also helps the storage tank perform its secondary job as a heat exchanger more efficiently. For an air compressor system with mean air consumption 1000 cfm maximum tank pressure 110 psi minimum tank pressure 100 psi and 5 sec time for the receiver to go from upper to lower pressure the volume of the receiver tank can be calculated by modifying 1 to. The change in level is detected by a level instrument which may be a simple bypass level gauge containing a.

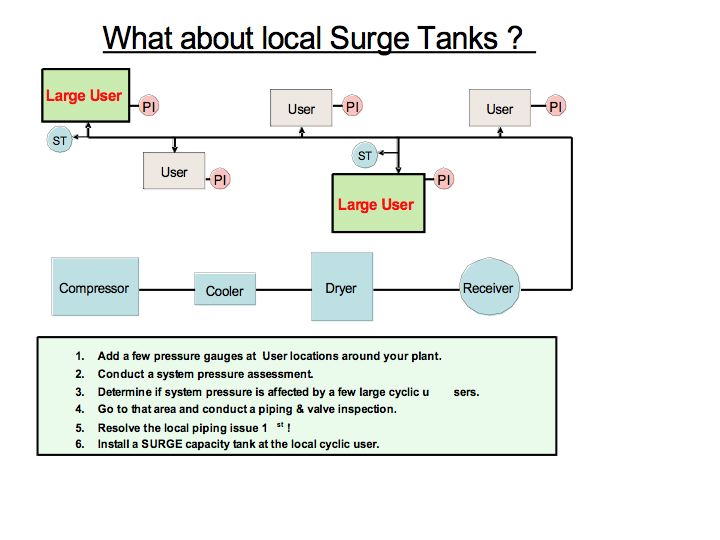

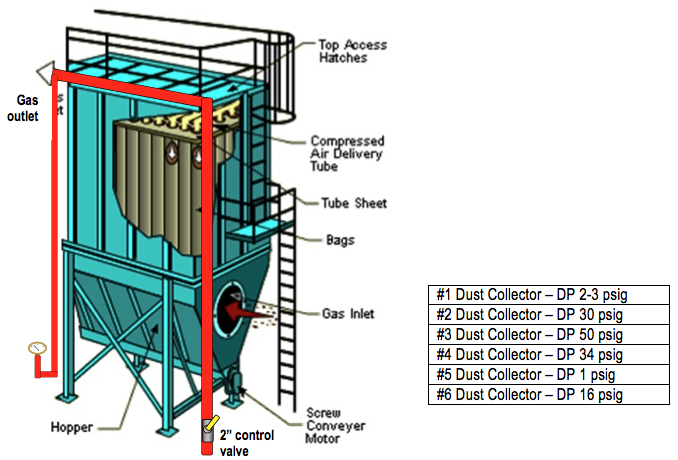

Choose the larger horizontal and vertical air tanks for commercial and industrial installations. Use small air receivers surge tanks ranging in capacity from 2 to 30 gal for point of use air storage. Aatanks air surge tanks are rated for 200 psi working pressures and are available in horizontal vertical and in line configurations. However there can never be enough storage for an air system.

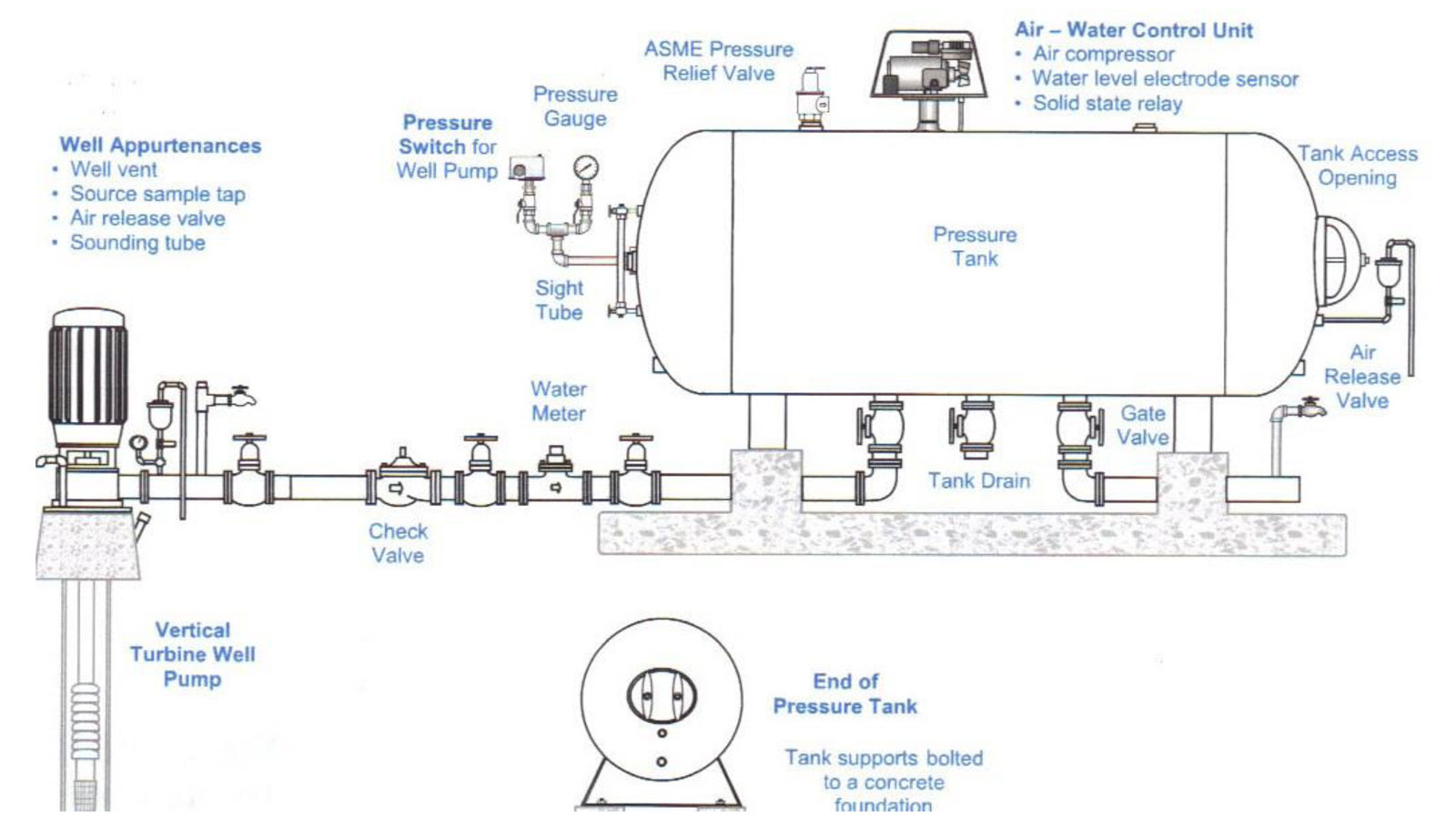

What to consider when choosing air tanks. Air surge tanks are designed to provide short bursts of compressed air for peak demand in pneumatic processes and for specific devices. Small air receiver surge tank is designed for point of use air storage. Separators are designed to eliminate entrained air or separate debris associated with start up and maintenance of any hydronic system.

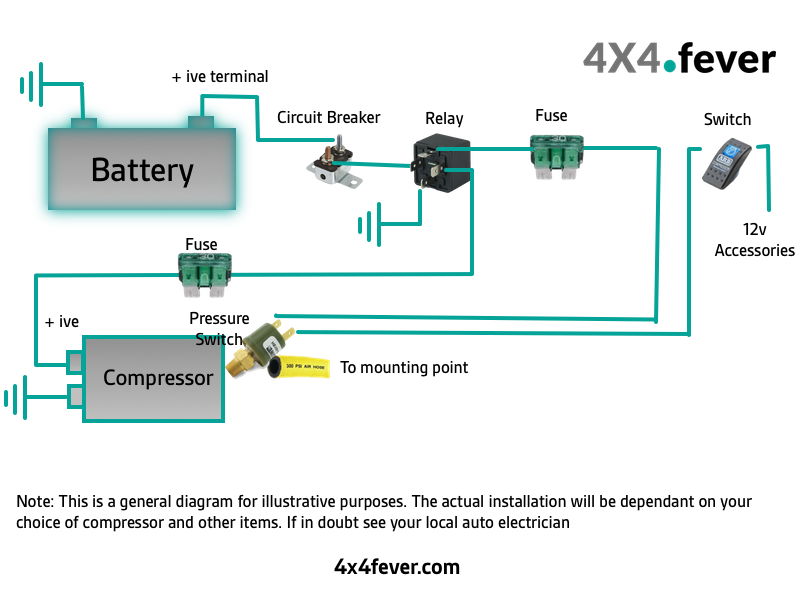

Sizing the recommended sizing for air compressor tanks is 4 gallons per cfm for rotary screw and piston air compressors and 2 gallons per cfm for variable drive compressors. The compressed air storage tank radiates heat as hot air from the compressor cools within the tank raising temperatures in the compressor room. In many applications using the tool will drain the tank and operators will need to wait for it to fill back up before more air can be used. Reciprocating air compressors use an air receiver tank to store air and eliminate pulsation before it can be used.

175 psi maximum working pressure. Aatanks asme code air surge tanks are designed to provide short bursts of compressed air for peak demand in pneumatic processes and for specific devices. Compressor surge tanks get a quotation frequently asked questions. Plugs included in all openings.

These steel horizontal tanks can efficiently provide compressed air to short peak demand applications. Ideally suited for commerical and industrial applications requiring the need for compressed air for short peak demand applications. The tank is a reservoir of compressed air that can be used during peak demand.

.jpg)