Compressed Air Dryer Types Pdf

Out of all the compressed air dryers the refrigerated dryer is the most popular and widespread type.

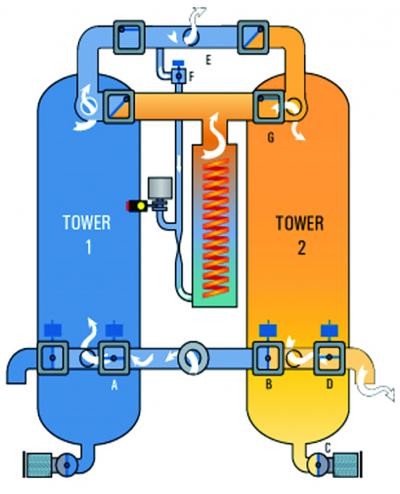

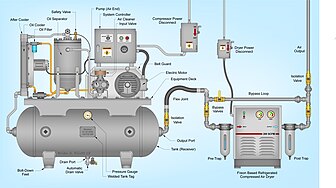

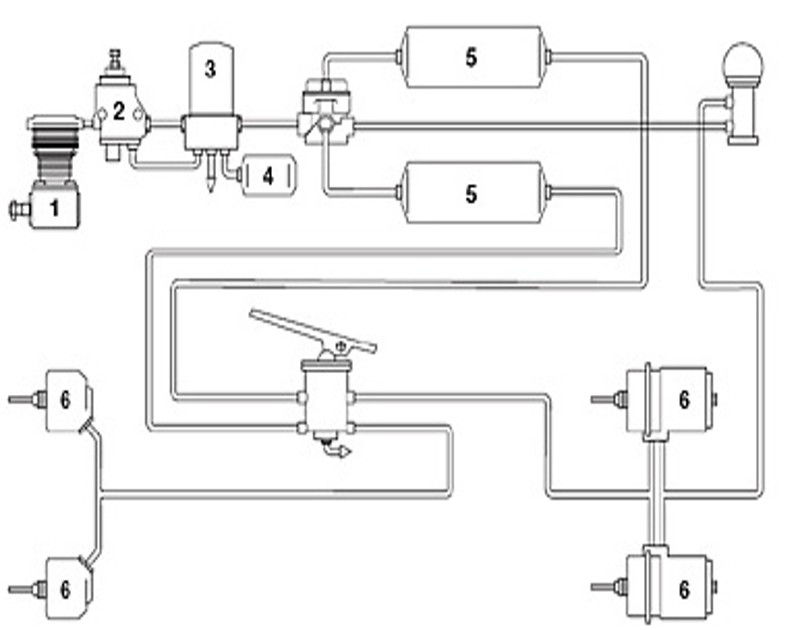

Compressed air dryer types pdf. The four main types of compressed air dryers are refrigerated chemical desiccant and membrane. The air is then reheated in an air to air heat exchanger by means of the incoming air which also is pre cooled before entering the air to refrigerant heat exchanger. Browse more oil by type. 2 compressed air ratings 3 types of compressors 4 system design considerations 5 compressor controls 6 compressor sizing 7 system configuration 8 air quality 9 components of compressed air system 10 compressed air treatment 11 after coolers 12 dryers 13 compressed air filters 14 six levels of compressed air treatment quality 15 receivers 16.

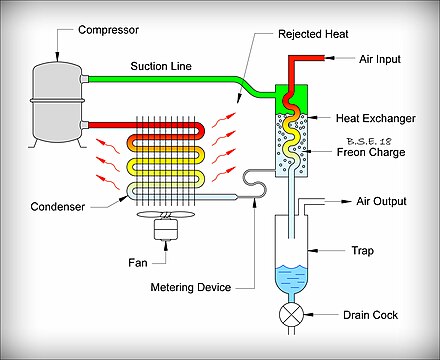

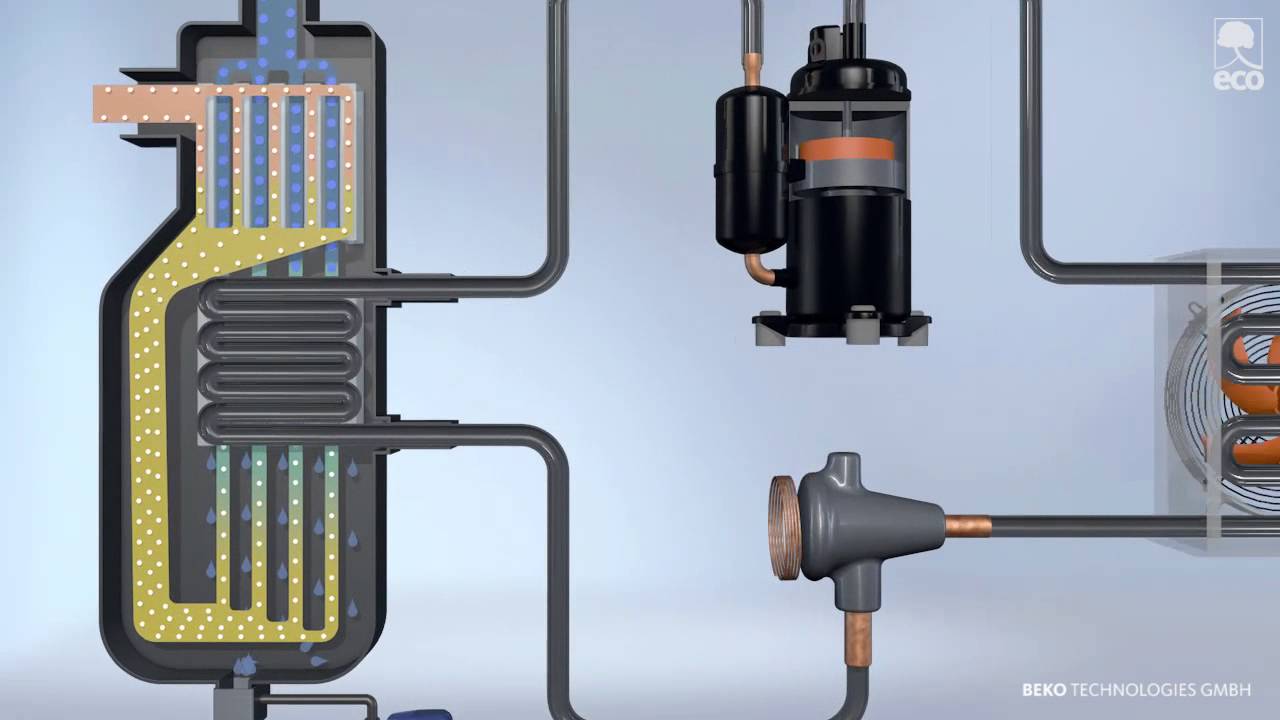

True to its name the refrigerated air dryer functions in a similar manner to home refrigerators in that a cooling process is employed that prevents moisture. Browse oil by manufacturer open accessories. A refrigerated dryer eliminates the problem by cooling moisture in the air to approximately 37 f where it condenses and can be removed from the compressor system by way of an automatic drain. They consist of an air to air heat exchanger and an air to freon heat exchanger.

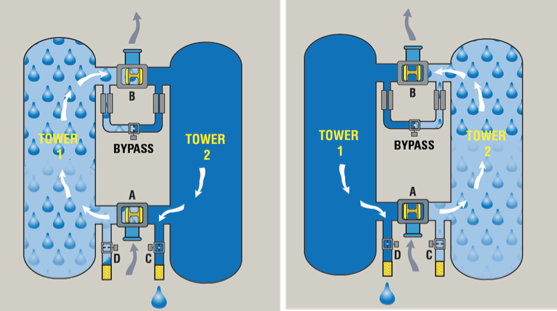

Desiccant air dryer vs. Refrigerated dryers work by cooling the air to low temperatures and condensing much of the water vapor. In this phase the incoming air is pre cooled by the outgoing air and the outgoing air is heated. The presence of water vapor in circulating air might alter chemical reactions involved in the manufacturing process and lead to the creation of poor quality products.

Refrigerated compressed air dryer types a lot of industrial processes require a steady flow of moisture free compressed air to optimize productivity. Compressed air dryers are special types of filter systems that are specifically designed to remove the water that is inherent in compressed air. Vacuum pump blower oil. The process of compressing air raises its temperature and concentrates atmospheric contaminants primarily water vapor.

All our air dryers are designed to perform in the most energy efficient and environmentally friendly way white paper compressed air drying 1 017 7 kb pdf. It is important to understand how each drying technology works to learn which is best for your application. Dryer parts accessories. The main difference is the objects or elements being cooled.

This means that the compressed air leaving the dryer has a pressure dew point of 35 to 40 f. Air preparation units. Gear bearing oil. With this moisture comes dirt and other particulate matter which can cause oxidation and other types of premature wear on delicate compressor components.

Consequently the compressed air is generally at an elevated temperature and 100 relative humidity.