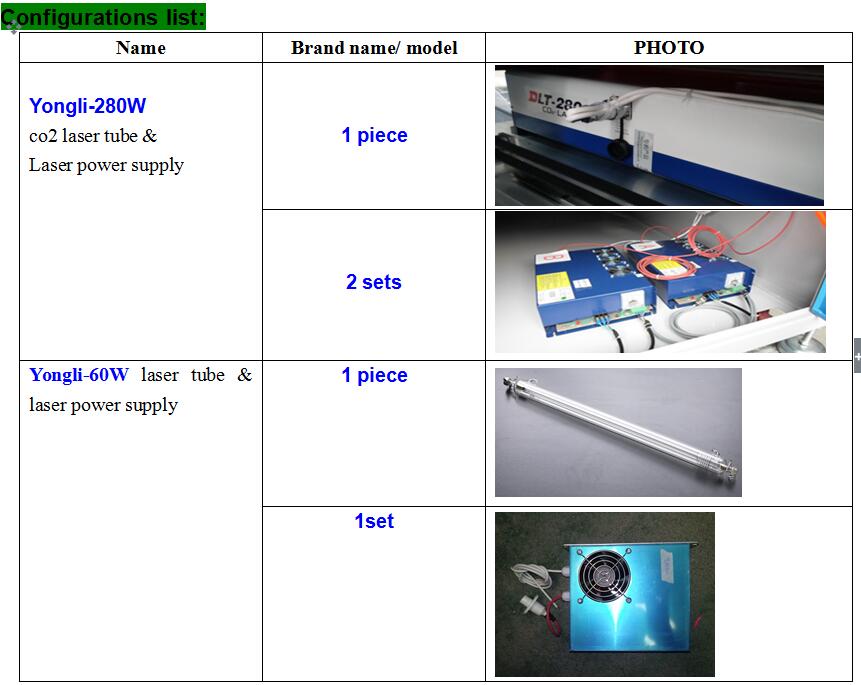

Co2 Laser Power To Cut Metal

Fiber laser has 1064nm whi.

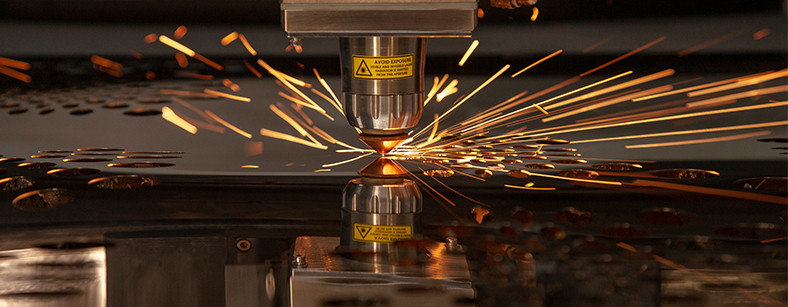

Co2 laser power to cut metal. Somehow the shorter the laser wavelength the finer the cutting. Fiber laser cutting technology is considered a disruptive and revolutionary change because it has impacted the entire status quo in sheet metal. This process is capable of holding quite close tolerances often to within 0 001 inch 0 025 mm part geometry and the mechanical soundness of the machine have much to do with tolerance capabilities. Will w mm 2 laser power cut on room temperature 25.

Cutting speed in meters per minute. Compact 4 x4 fiber laser metal sheet cutting machine 500 3000 w from. We tried cutting metals with 100w laser which is much higher power than our 40w laser cutter. Laser power in kw some new laser cutters have laser power of 4 kw.

Mike klos laser mechanisms converting to millimeters that s 1550 watts mm 2. Sheet metal cutting requires a power density of 10 6 watts in 2 source. Steel sheet thickness in mm. Laser cutting materials offers craftsmen and manufacturers precision results utilizing the power of lasers and the strength of co2.

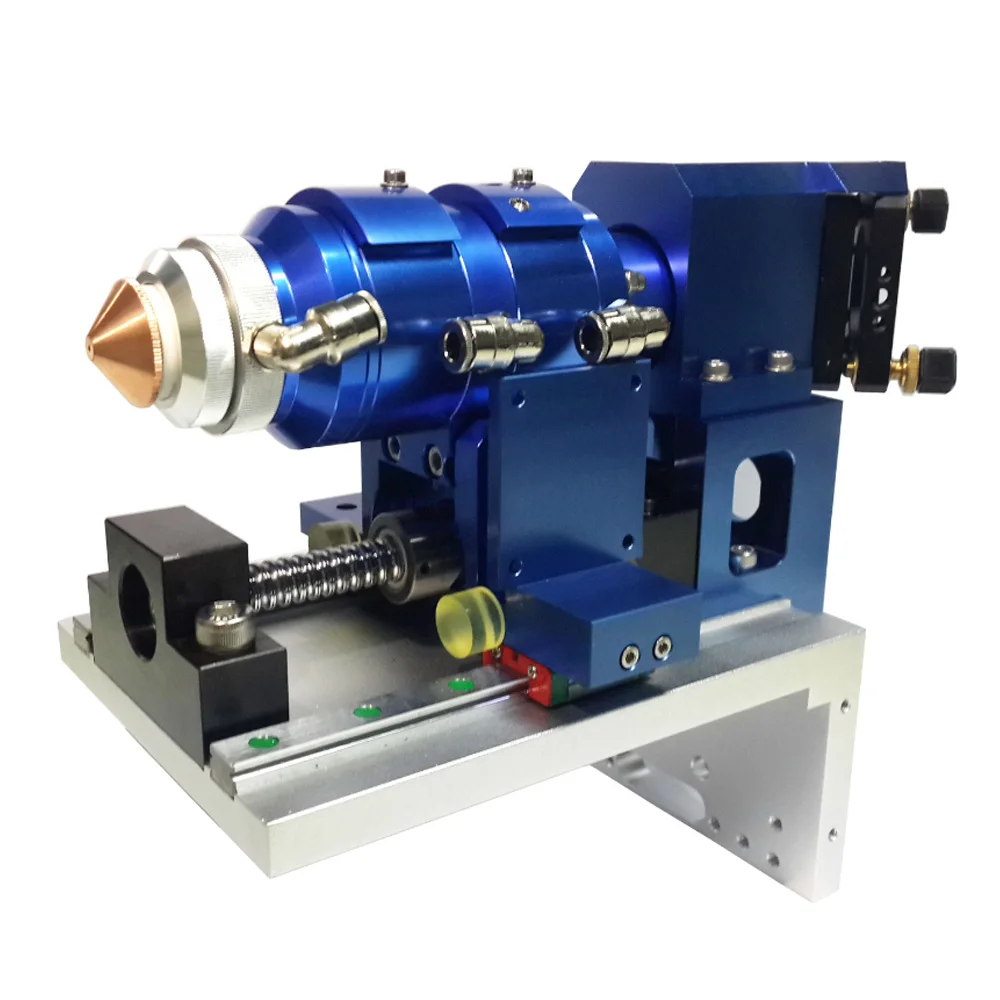

Before beginning any cutting project always inspect your machine observe the chiller temperature and gauge your interior temperature to meet the wattage demands of your cutter. A small air pump is included and functions as the default cutting air source for all our co2 laser cutting tables. Read more about our trial in our blog http www smartdiys cc b. 1in 2 645mm 2 a 100 watt laser can achieve a power density of 1550 watts mm 2 in a spot size that is 0 6452mm 2 a spot size that is 0 6452mm 2 has a diameter of of 28mm or 280 micron using area pi d 2 2 280 micron.

As the cutting air compound may require to be replaced with oxygen or other metal cutting assistance gas for better cutting quality. Metal laser cutting does not rely on pure laser power in cutting process.

.jpg)