Clean Room Hvac Design Guide

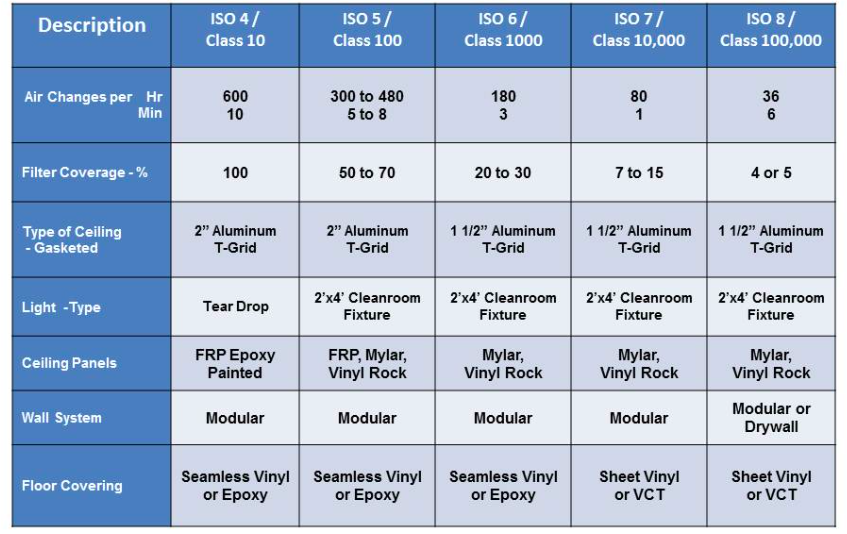

Supplying airflow in sufficient volume and cleanliness to support the cleanliness rating of the room.

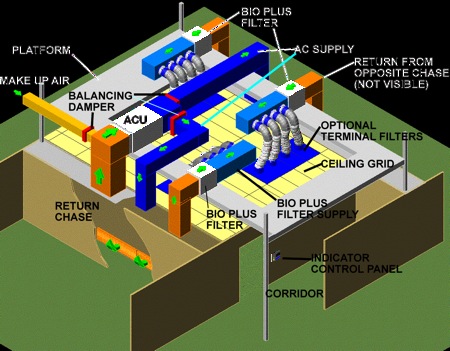

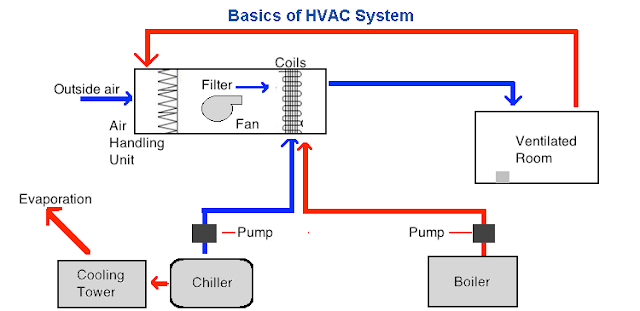

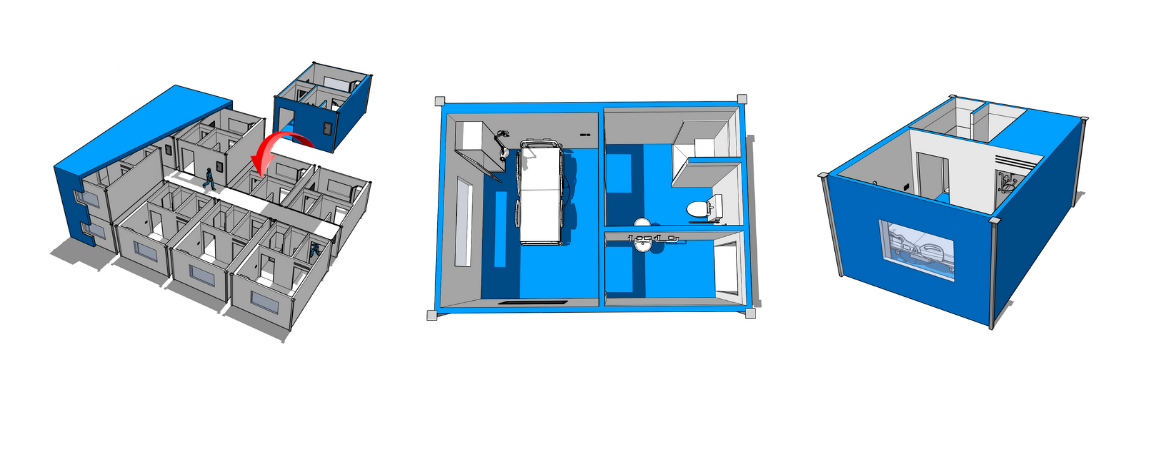

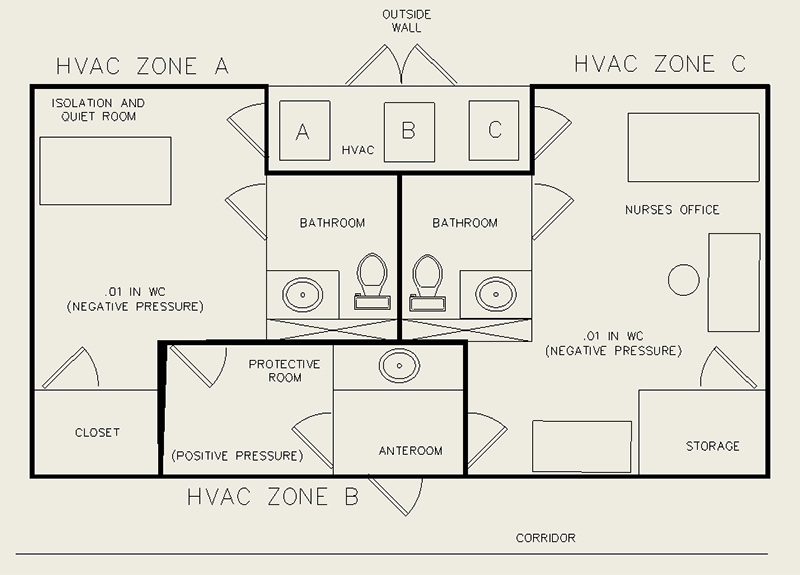

Clean room hvac design guide. It offers an approachable technical perspective to designers builders owners and operators of cleanrooms. 100 outside air delivery to plenum temperature and humidity control of make up air 6 units each sized for 30 000 cfm make up air flow is 5 cfm sf or 25 ach. The hvac system requirements include. The ashrae design guide for cleanrooms offers a practical comprehensive approach to cleanroom theories fundamentals performance control testing and industrial applications.

Supplying airflow in sufficient volume and cleanliness to support the cleanliness rating of the room. They should be computed by an hvac cleanroom expert as many aspects must be taken into consideration such as the size of the room the number of people in the room the equipment in the room the processes involved the heat gain etc. A guide to hvac systems design. Ashrae clean spaces technical committee tc9 11 chairman 07 10 healthcare facilities technical committee tc9 6 member laboratory systems technical committee tc9 10 member iest working group cc012 cleanroom design chairman president.

A guide to cleanroom design. Last but certainly not least the degree of precision you need will also influence the design of the hvac system. Hvac design clean room make up air ahus. The first will discuss the fundamentals of cleanrooms and hvac systems design including the classifications of cleanrooms cleanroom iso standards design and testing guidelines by ashrae and nebb particulate sources from indoor and outdoor and their impacts on cleanroom air cleanliness.

Hvac systems design fundamentals karachi pakistan february 22 2011 wei sun p e. The 4 important air conditioning design considerations for clean room system design are. The above suggested air changes per hour are only a design rule of thumb. Introducing air in a manner to prevent stagnant areas where particles could accumulate.

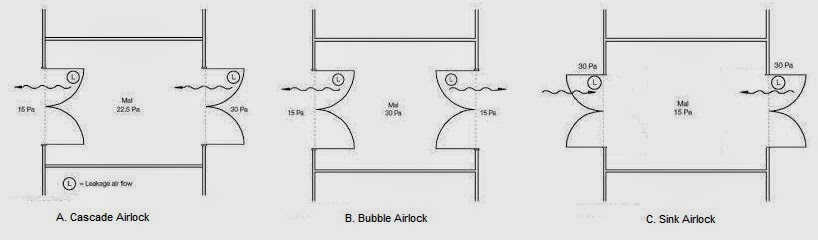

A cleanroom is a room or space in which the level of particulate contamination is controlled within set levels. The precision level required. This course will consist of two segments. The construction temperature humidity air flow patterns and pressure are controlled in such a way as to minimise the introduction generation and.

40 units each sized for 24 000 cfm. 2 the hvac system the integrity of the cleanroom environment is created by the pressure differential compared with adjacent areas through heating ventilation and air conditioning system. Learning points include standards and classifications p.